100L High and Low Temperature Circulating Device by Hefei Yangmai Technology Instrument Co., Ltd is engineered for advanced temperature regulation in laboratory-scale chemical reactions. Featuring a fully enclosed circulation loop, LED touchscreen controller, and dual-function heating/cooling capabilities, it delivers accurate performance from -30℃ to 200℃. Ideal for supporting glass reactors in flammable or sensitive environments, this system ensures stable operation, minimal thermal loss, and enhanced user safety through multi-level protection features and Siemens-grade PLC integration.

| Model |

YMJGD-5EX |

YMJGD-20EX |

YMJGD-50EX |

YMJGD-100EX |

YMJGD-150EX |

YMJGD-200EX |

YMJGD-500EX |

YMJGD-2000EX |

| Tem range |

-25-180℃ |

-30-200℃ |

| Setting&display |

10 inch color touch screen |

| Tem accuracy |

±0.5℃ |

| Control Mode |

Touch screen configuration PLC control |

| Communication Protocol |

MODBUS RTU protocol RS485 communication interface |

| Temperature control options |

Jacket temperature control |

| PLC Module |

Siemens S7-200 |

| Refrigeration system |

Two-stage cascade refrigeration technology |

| Heating Power |

2.4KW |

3.5KW |

5KW |

7.5KW |

9KW |

12KW |

40KW |

70KW |

| Cooling capacity(-20℃) |

3.5KW |

4.5KW |

6KW |

7.5KW |

9KW |

12KW |

|

|

|

Pump flow

|

20L/min |

40L/min |

56L/min |

| Pump pressure |

0.4bar |

0.8bar |

0.5-1.5bar |

| Compressor |

Embraco |

Emerson Copeland |

| Evaporator |

Plate heat exchanger |

| Expansion valve |

Danfoss |

| Safety protection |

Self-diagnosis, compressor overload protection, exhaust pressure protection, circulating pump overload pressure Danfoss protection, low liquid level protection, phase loss and out-of-phase protection, etc. |

| Refrigerant |

R404A eco-friendly refrigerant |

| Shell material |

Cold rolled plate spraying |

| Pipe material |

SUS304 |

| Power supply |

220V/50HZ |

380V/50HZ |

| Weight(KG) |

80 |

150 |

160 |

180 |

210 |

230 |

580 |

900 |

| Dimention(CM) |

50*56*83 |

62*72*102 |

65*75*107 |

65*75*136 |

65*75*136 |

65*75*136 |

90*130*160 |

130*170*190 |

| Optional |

Temperature range:-105~300℃ |

| Optional |

Shell material:SUS304 |

| Optional |

Tecumseh, Danfoss compressor |

| Optional |

Optional explosion-proof models |

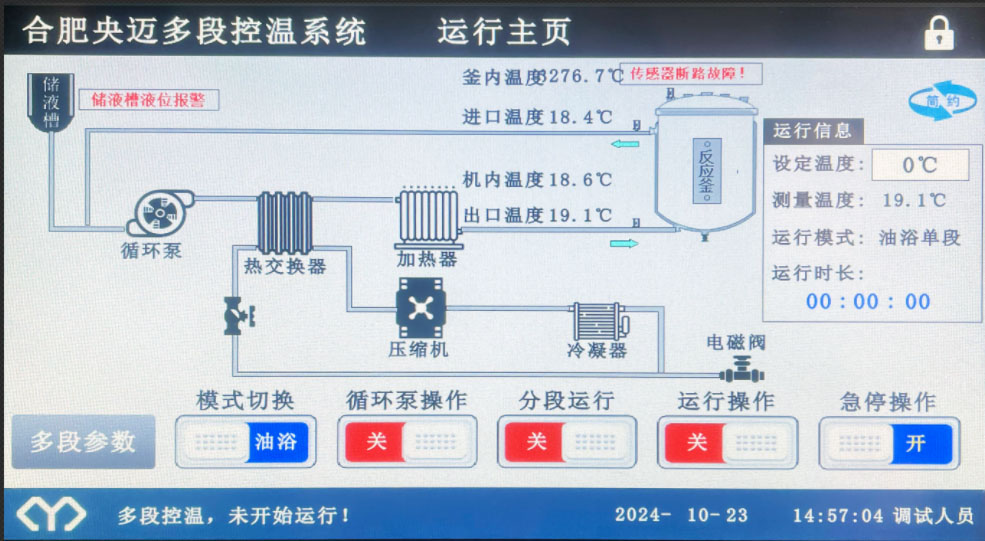

10-inch touch screen +Siemens module system +Independent research

and development procedures

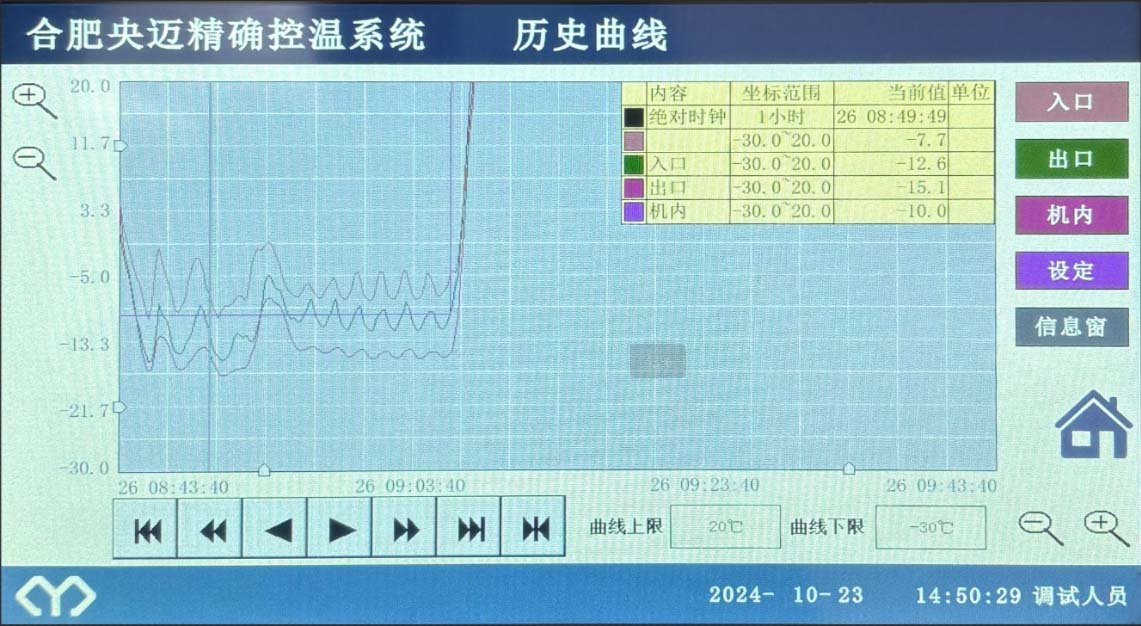

Temperature control curve:

Constant temperature control in the kettle

Switchable control of jacket temperature

(485 communication interface output printing)

1.Wide Operating Temperature Range

Supports both heating and cooling, with a standard range from -30℃ to 200℃, meeting the demands of most laboratory temperature control applications.

2.10-Inch Touchscreen Control Interface

Features an intuitive LED touchscreen that displays real-time system status, historical curves, and data logs. Data can be easily exported for analysis, ensuring simple and reliable operation.

3.Efficient & Easy to Use

Designed for high-speed temperature transitions and quick, simplified filling and draining processes, minimizing downtime.

4.Fully Sealed Circulation System

The closed-loop system eliminates oil mist and prevents water absorption, ensuring a safer working environment and extending the lifespan of the thermal fluid.

5.Reliable Cooling System

Features a high-performance American Copeland compressor known for its durability, low noise level, and consistent refrigeration output.

6.Advanced Safety Protections

Integrated with a self-diagnosis system, overload protection, high-pressure switch, thermal cut-off, and alarm relay to ensure safe and stable operation.

7.Consistent Medium Management

The same heat transfer fluid is used throughout the heating and cooling process, reducing contamination risk and improving thermal response efficiency.

8.High-Lift Pump Design

Enables the circulation of thermal fluid across long distances or vertically positioned glass reactors in complex lab setups.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.