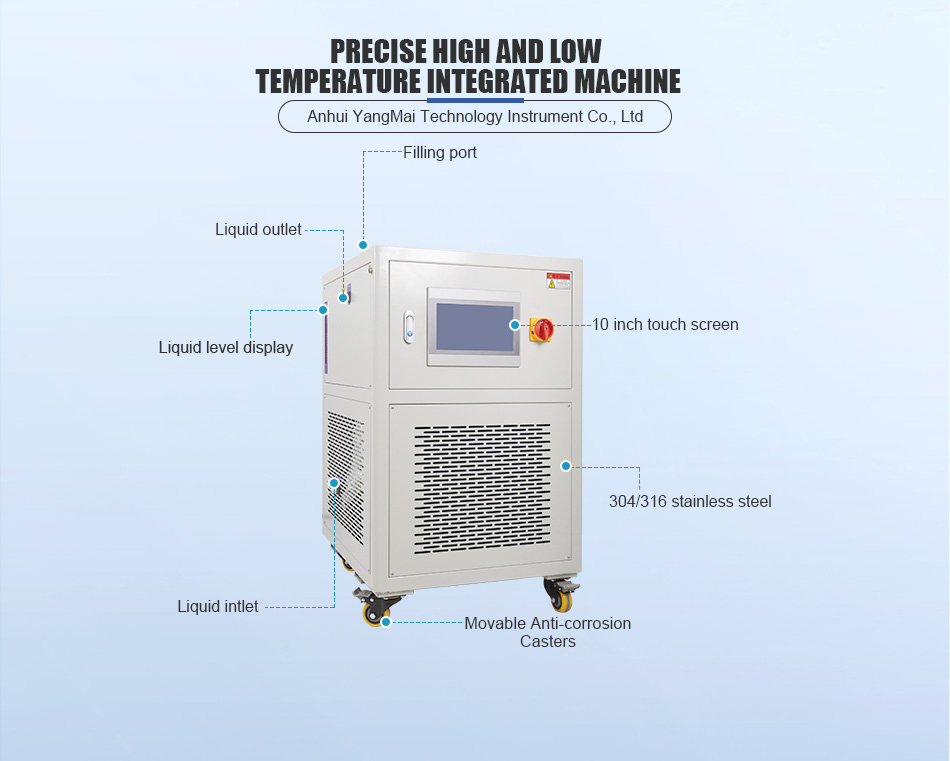

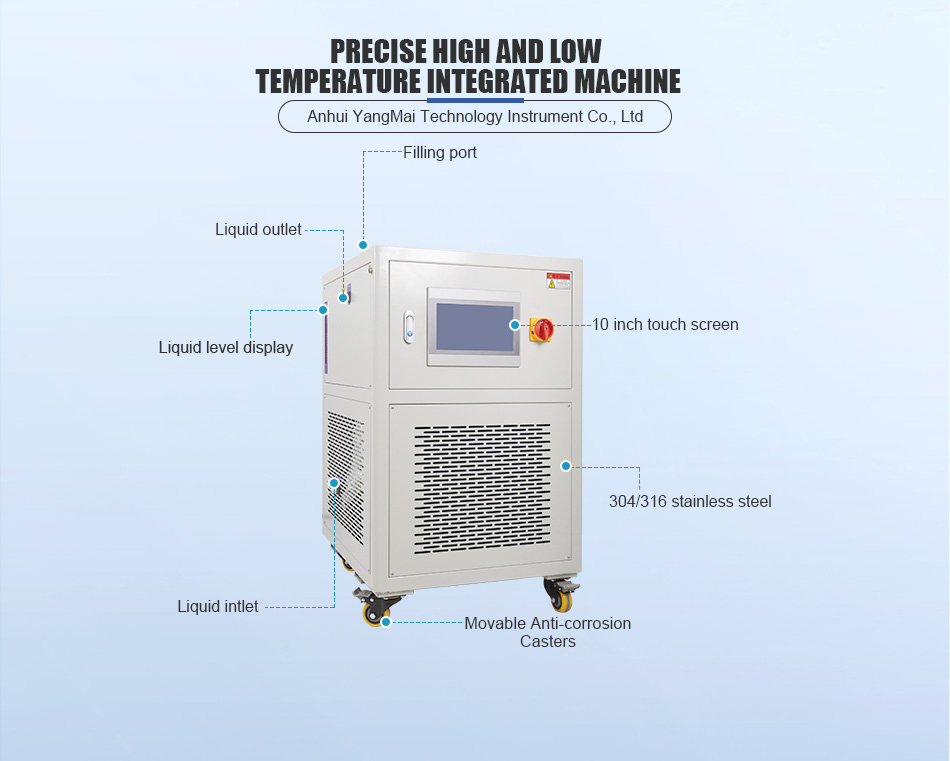

200L Precise Temperature Control Heating and Cooling Circulator by Hefei Yangmai Technology Instrument Co., Ltd is engineered for demanding chemical and laboratory applications, this 200L sealed temperature control system offers accurate heating and cooling within a wide range of -30℃ to 200℃. Its LED touchscreen provides real-time monitoring and simple operation, while the fully closed-loop design prevents oil mist and contamination. Compatible with glass reactors and other jacketed vessels, it ensures stable thermal performance with minimal maintenance, making it the ideal solution for precision-controlled experiments.

| Model |

YMGD-5 |

YMGD-20 |

YMGD-50 |

YMGD-100 |

YMGD-150 |

YMGD-200 |

YMGD-500 |

YMGD-2000 |

| Tem range |

-25-180℃ |

-30-200℃ |

| Setting&display |

10 inch color touch screen |

| Tem accuracy |

±0.5℃ |

| Control Mode |

Touch screen configuration PLC control |

| Communication Protocol |

MODBUS RTU protocol RS485 communication interface |

| Temperature control options |

Jacket temperature control |

| PLC Module |

Siemens S7-200 |

| Refrigeration system |

Two-stage cascade refrigeration technology |

| Heating Power |

2.4KW |

3.5KW |

5KW |

7.5KW |

9KW |

12KW |

40KW |

70KW |

| Cooling capacity(-20℃) |

3.5KW |

4.5KW |

6KW |

7.5KW |

9KW |

12KW |

|

|

|

Pump flow

|

20L/min |

40L/min |

56L/min |

| Pump pressure |

0.4bar |

0.8bar |

0.5-1.5bar |

| Compressor |

Embraco |

Emerson Copeland |

| Evaporator |

Plate heat exchanger |

| Expansion valve |

Danfoss |

| Safety protection |

Self-diagnosis, compressor overload protection, exhaust pressure protection, circulating pump overload pressure Danfoss protection, low liquid level protection, phase loss and out-of-phase protection, etc. |

| Refrigerant |

R404A eco-friendly refrigerant |

| Shell material |

Cold rolled plate spraying |

| Pipe material |

SUS304 |

| Power supply |

220V/50HZ |

380V/50HZ |

| Weight(KG) |

80 |

150 |

160 |

180 |

210 |

230 |

580 |

900 |

| Dimention(CM) |

50*56*83 |

62*72*102 |

65*75*107 |

65*75*136 |

65*75*136 |

65*75*136 |

90*130*160 |

130*170*190 |

| Optional |

Temperature range:-105~300℃ |

| Optional |

Shell material:SUS304 |

| Optional |

Tecumseh, Danfoss compressor |

| Optional |

Optional explosion-proof models |

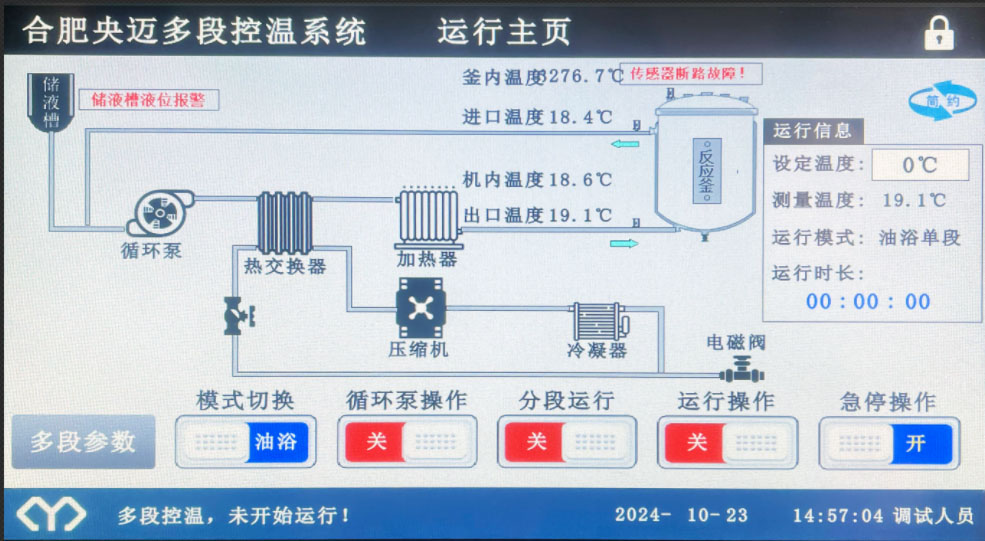

10-inch touch screen +Siemens module system +Independent research

and development procedures

--

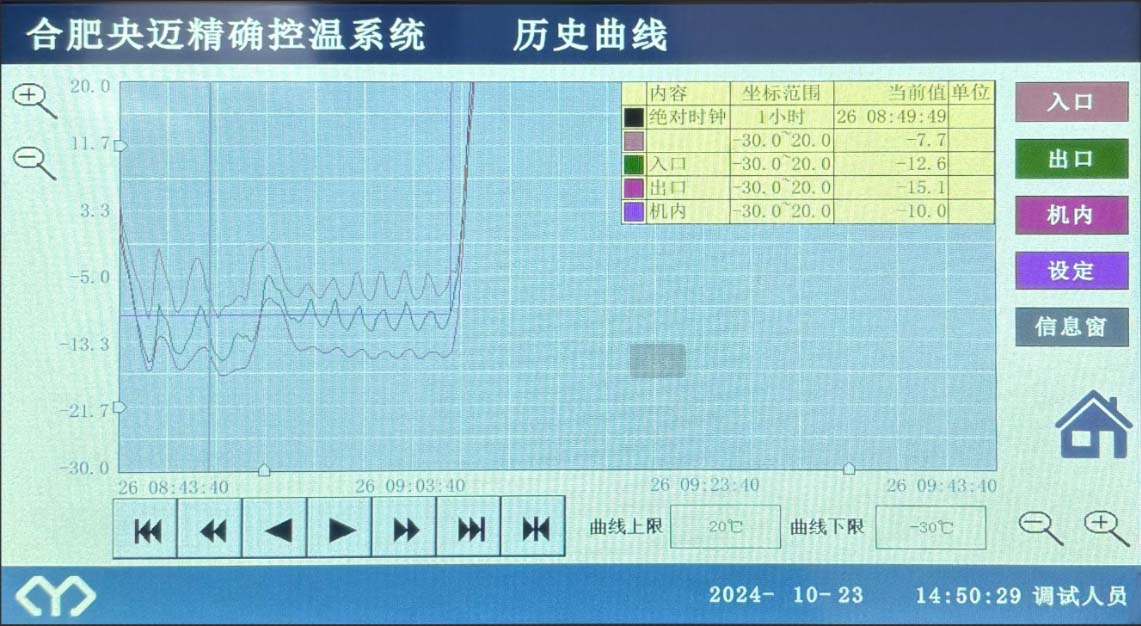

Temperature control curve:

Constant temperature control in the kettle

Switchable control of jacket temperature

(485 communication interface output printing)

1.Extended Temperature Operating Range

Offers integrated heating and cooling from -30℃ to 200℃, with optional customization for broader applications.

2.10-Inch Smart LED Touch Display

Equipped with a responsive LED panel for system status viewing, trend analysis, and easy data export to simplify lab operations.

3.Smooth High-Low Temperature Switching

Enables rapid transitions across wide temperature spans, maintaining stability even under extreme conditions.

4.Fully Sealed Thermal Circulation System

A closed-loop design eliminates vapor loss and moisture entry, ensuring safe operation and extended fluid integrity.

5.High-Performance Copeland Compressor

Utilizes a trusted American compressor brand for consistent cooling output and long-term reliability in demanding environments.

6.Multi-Tier Safety Protection System

Integrated with layered safety protocols, including thermal fuses, relay protections, and overcurrent sensors.

7.Uniform Heat Transfer Fluid Management

Employs a single-loop fluid system to ensure constant media properties and avoid cross-contamination during operation.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.