Why Choose Borosilicate Glass Reactors for Organic Chemistry?

Sep 24, 2025

Organic chemistry experiments require precise control, safety, and visibility during chemical reactions. Borosilicate glass reactors have become the preferred choice in laboratories and pilot plants due to their unique combination of chemical resistance, thermal stability, and transparency. Here’s why borosilicate glass reactors are essential for organic chemistry.

Excellent Chemical Resistance

Borosilicate glass is highly resistant to acids, bases, and most organic solvents. This property ensures that the reactor does not react with the chemicals inside, preventing contamination and maintaining the purity of the reaction products. Whether you are performing synthesis, crystallization, or distillation, borosilicate glass offers a reliable solution.

Superior Thermal Stability

Many organic chemistry reactions require precise heating or cooling. Borosilicate glass can withstand rapid temperature changes and high temperatures without cracking. Its thermal stability allows researchers to safely perform reflux reactions, heating under vacuum, or cooling sensitive compounds, making experiments more efficient and predictable.

Transparent Design for Real-Time Observation

Unlike metal reactors, borosilicate glass reactors provide full visibility of the reaction process. Researchers can monitor color changes, precipitation, and phase separation in real time, which is crucial for reaction optimization and quality control.

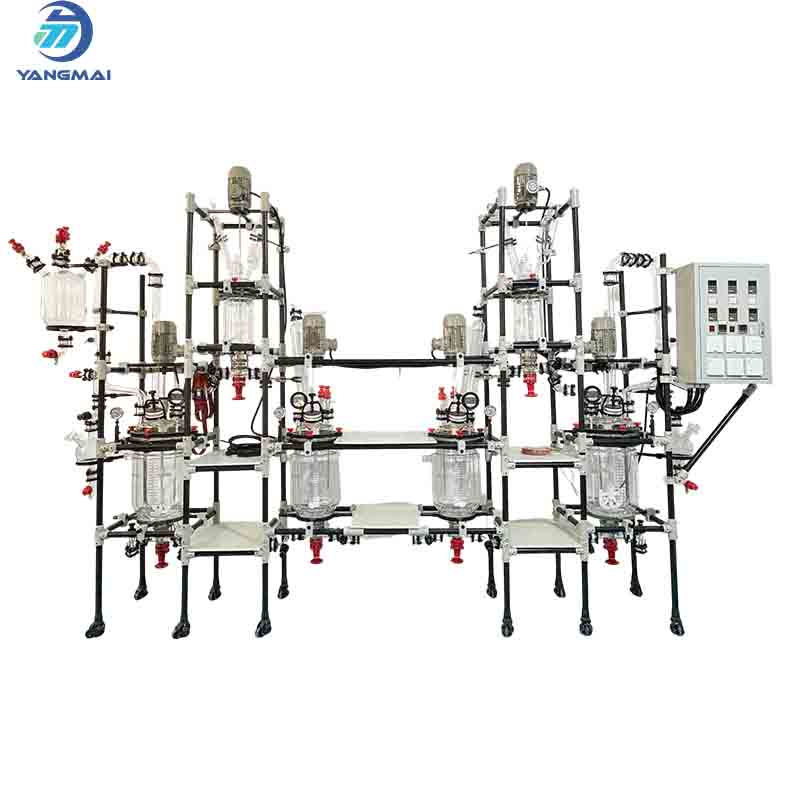

Modular and Versatile Configurations

Borosilicate glass reactors often come with modular designs, allowing integration of stirrers, condensers, vacuum systems, and addition funnels. This flexibility is perfect for small-scale organic synthesis, pilot plant experiments, and laboratory research. You can customize the setup for heating, cooling, vacuum distillation, or multi-step synthesis.

Safety and Durability

High-quality borosilicate glass is strong and corrosion-resistant, reducing the risk of leaks and breakage. Combined with stainless-steel frames and secure clamps, these reactors provide safe operation even under high pressure or vacuum conditions, ensuring reliable results in organic chemistry labs.

Conclusion

For organic chemistry research and pilot-scale experiments, borosilicate glass reactors are the ideal choice. They combine chemical resistance, thermal stability, transparency, and modularity to meet the demanding needs of modern laboratories. Investing in a borosilicate glass reactor ensures safe, efficient, and high-quality chemical reactions.