Common Issues and Solutions of Double-Layer Glass Reactor

May 27, 2025

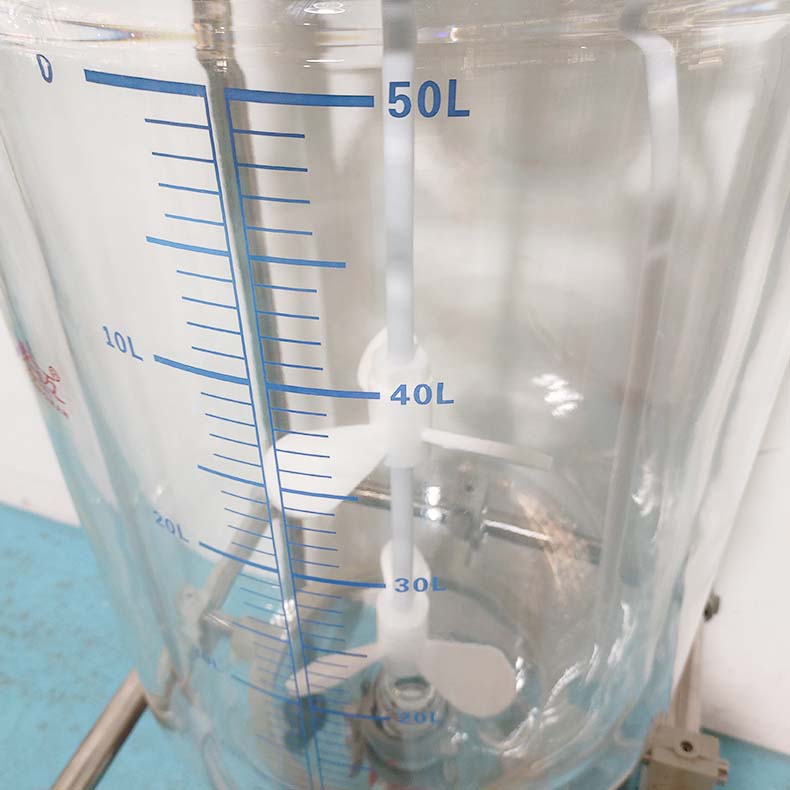

Double-layer glass reactors are widely used in laboratory and industrial applications for their visibility, stable temperature control, and strong corrosion resistance. However, during actual operation, some common issues may arise. Based on user feedback, YangMai Technology Instrument summarizes several frequent problems and offers corresponding solutions below:

Issue 1: Poor Circulation or Slow Heating in the Jacket

Possible Causes: Pipeline blockage, insufficient pump flow, or high-viscosity thermal fluid.

Solutions:

1. Check if the pipeline or jacket has air blocks or debris; flush the circulation system if needed.

2. Replace with a circulation pump with a higher flow rate for improved efficiency.

3. Use recommended low-viscosity heat transfer fluids (e.g., ethanol or silicone oil).

Issue 2: Leakage Due to Poor Sealing

Possible Causes: Worn dynamic seals on the stirring shaft, loose flange connections, or aging PTFE gaskets.

Solutions:

1. Inspect the mechanical seal on the shaft; replace O-rings or gaskets if necessary.

2. Reinstall glass connections securely and ensure PTFE gaskets are intact.

3. Perform regular maintenance on sealing components to ensure long-term airtight performance.

Issue 3: Fragility or Breakage of Glass Parts

Possible Causes: Improper handling, inadequate transport protection, or uneven external force.

Solutions:

1. Avoid impact or sudden temperature changes (e.g., do not flush with cold liquid after heating).

2. Use custom foam packaging or wooden crates for transport.

3. If broken, glass parts can be individually replaced without affecting the entire unit.

At YangMai, we focus on detail, durability, and ease of maintenance in every reactor system. All equipment undergoes rigorous factory testing and standardized assembly before shipment. We also provide professional technical support to help our customers minimize downtime and ensure smooth, continuous experiments.

For technical manuals, maintenance guides, or operation videos, feel free to contact us anytime!