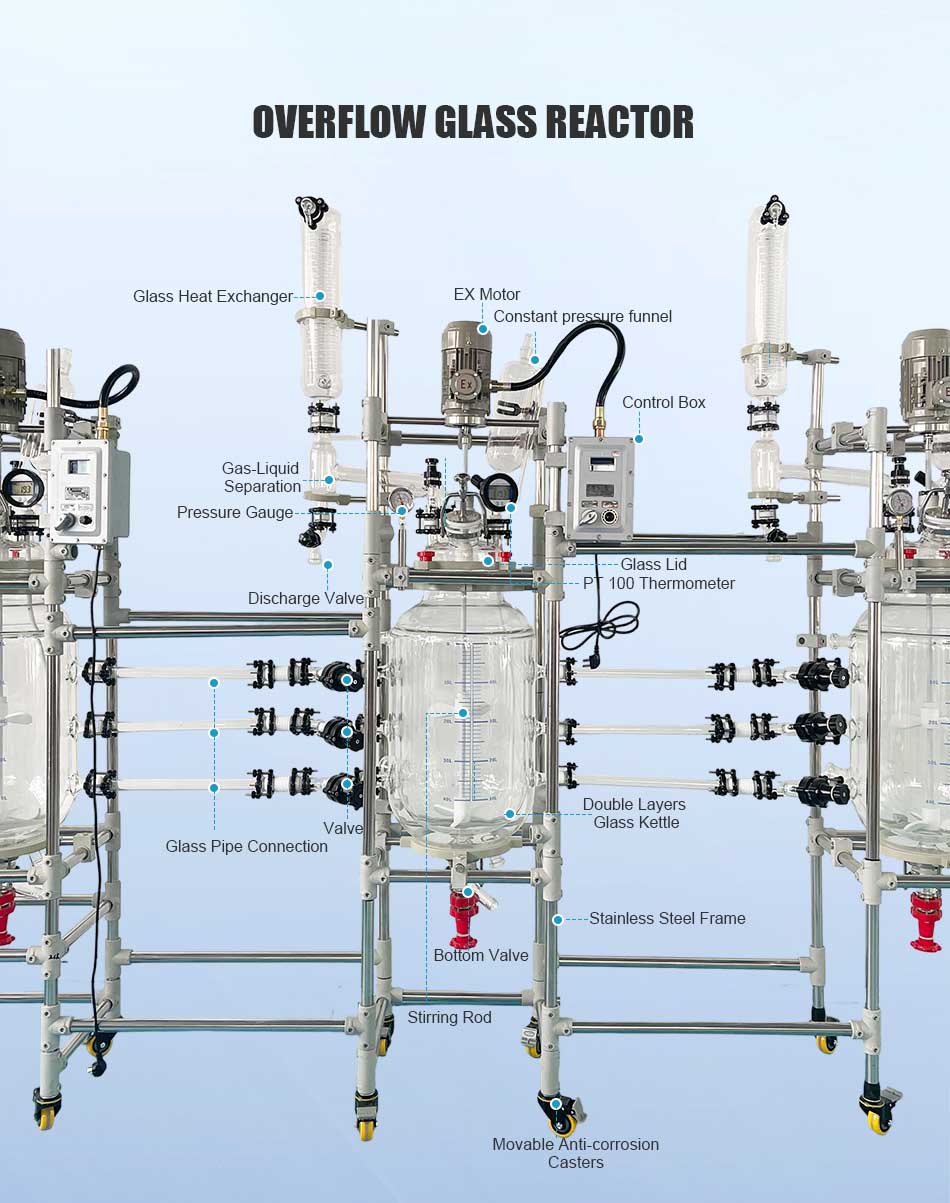

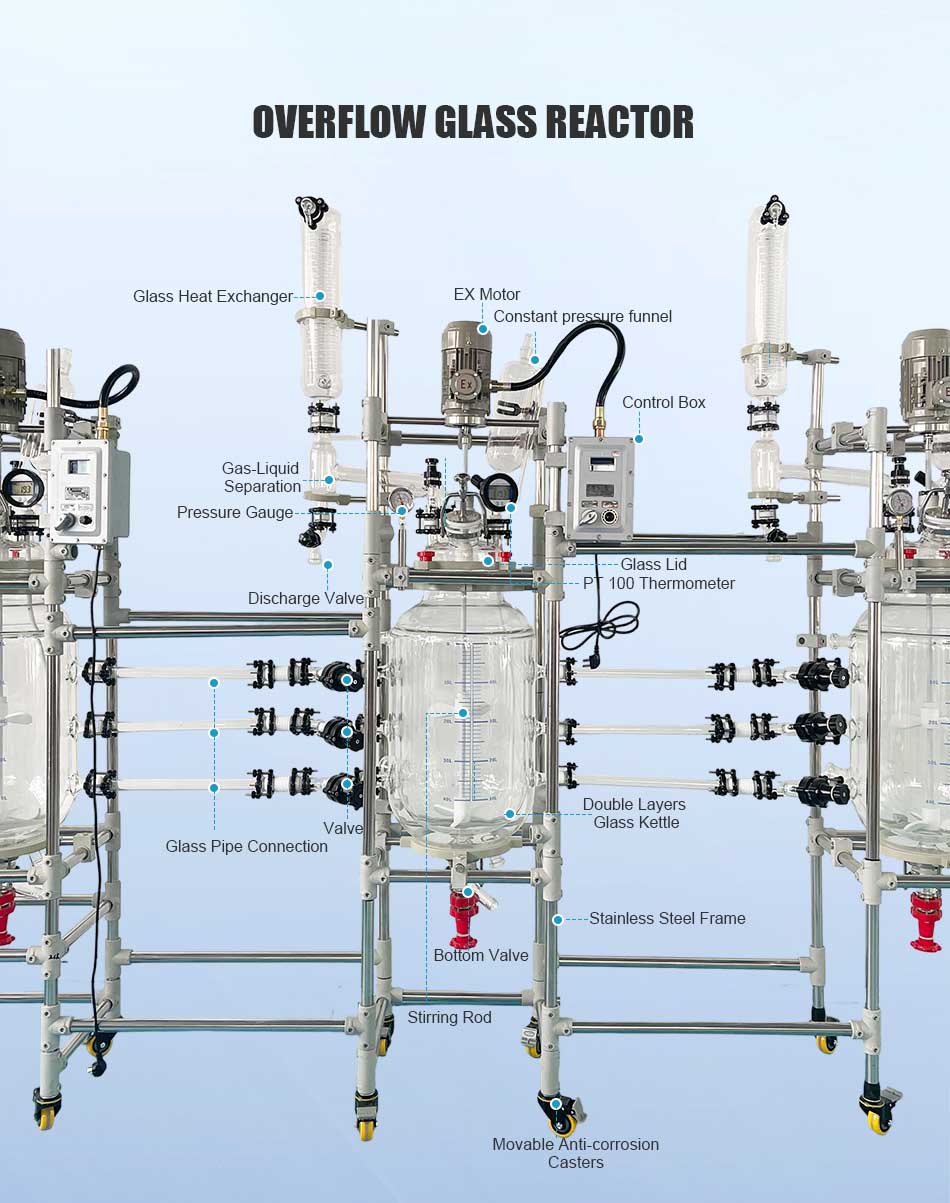

The Overflow Glass Reactor by Hefei Yangmai Technology Instrument Co., Ltd is suitable for organic synthesis, API preparation, and pilot-scale production, this reactor supports high-temperature and pressure-resistant reactions. Its overflow design ensures precise volume control, enabling continuous feeding and discharge. The modular setup allows easy integration with condensers, dosing pumps, and vacuum systems, making it a versatile tool in any lab or industrial plant.

|

Model

|

Volume(L) |

Motor power(w) |

Vaccum degree(Mpa) |

Speed

(Ram)

|

Torque

(Ncm)

|

Power supply |

Size(Cm) |

| YMGR-01 |

1 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-02 |

2 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-05EX |

5 |

180 |

0.096 |

50~600 |

44 |

220V/50HZ |

45*45*110 |

| YMGR-10EX |

10 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*120 |

| YMGR-20EX |

20 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*145 |

| YMGR-30EX |

30 |

180 |

0.096 |

50~600 |

210 |

220V/50HZ |

50*50*160 |

| YMGR-50EX |

50 |

180 |

0.096 |

50~600 |

300 |

220V/50HZ |

60*60*180 |

| YMGR-100EX |

100 |

370 |

0.096 |

50~600 |

400 |

220V/50HZ |

70*70*260 |

| YMGR-150EX |

150 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

85*85*290 |

| YMGR-200EX |

200 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

90*90*300 |

1. Continuous Overflow Reaction

Designed with a fixed overflow outlet, enabling stable liquid levels for continuous separation, discharge, or crystallization during extended chemical reactions.

2. Corrosion and Temperature Resistance

Constructed with borosilicate glass, PTFE lining, or stainless steel options, providing excellent chemical resistance and stability under high-temperature conditions.

3. Integrated Jacketed Heating and Cooling

Features a jacketed design for precise thermal control, allowing integration with thermostatic circulators for controlled heating or cooling operations.

4. Versatile Application Design

Suitable for pharmaceutical synthesis, crystallization, extraction, or fermentation processes. Compatible with batch or semi-continuous workflows.

5. Easy Maintenance and Cleaning

Detachable structure and smooth internal surface simplify maintenance and cleaning, ensuring high operational efficiency and GMP compliance.

6. Easy Maintenance and Cleaning

Available in various capacities (5L to 500L+), with optional accessories such as sensors, condensers, or automation control valves.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.