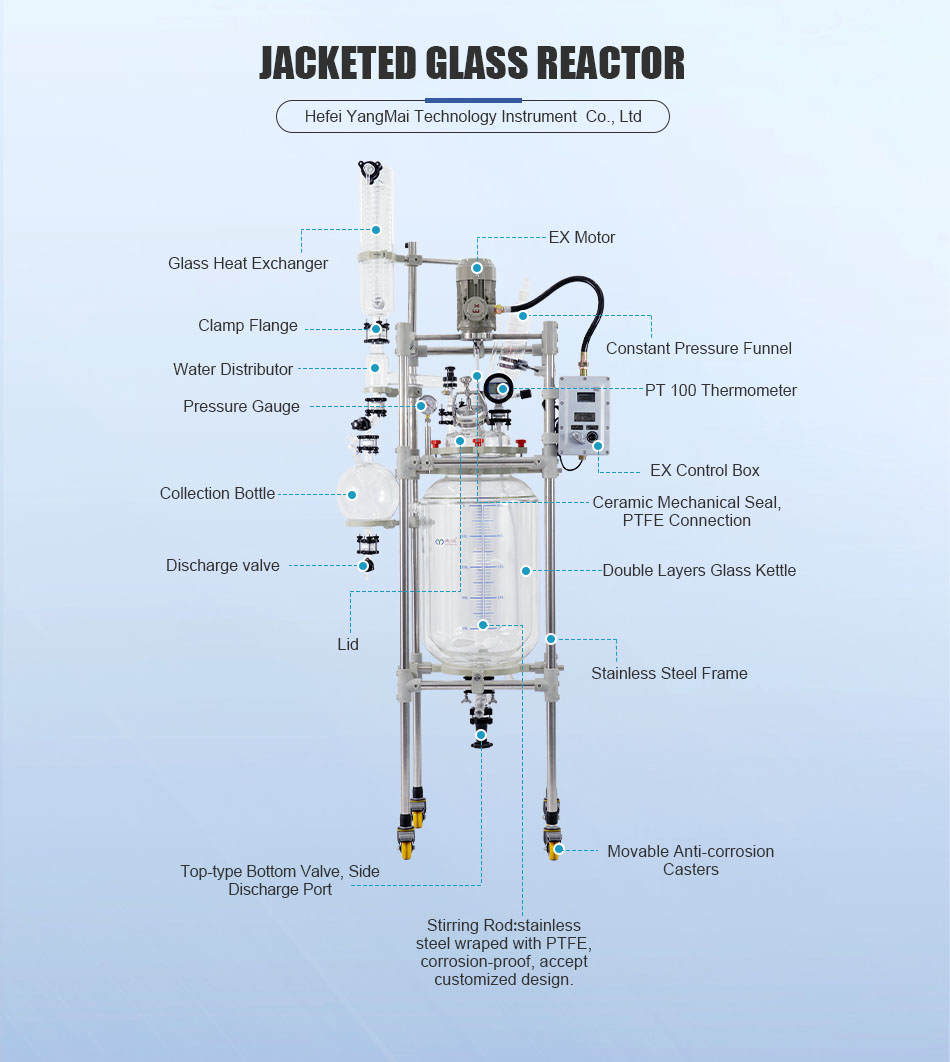

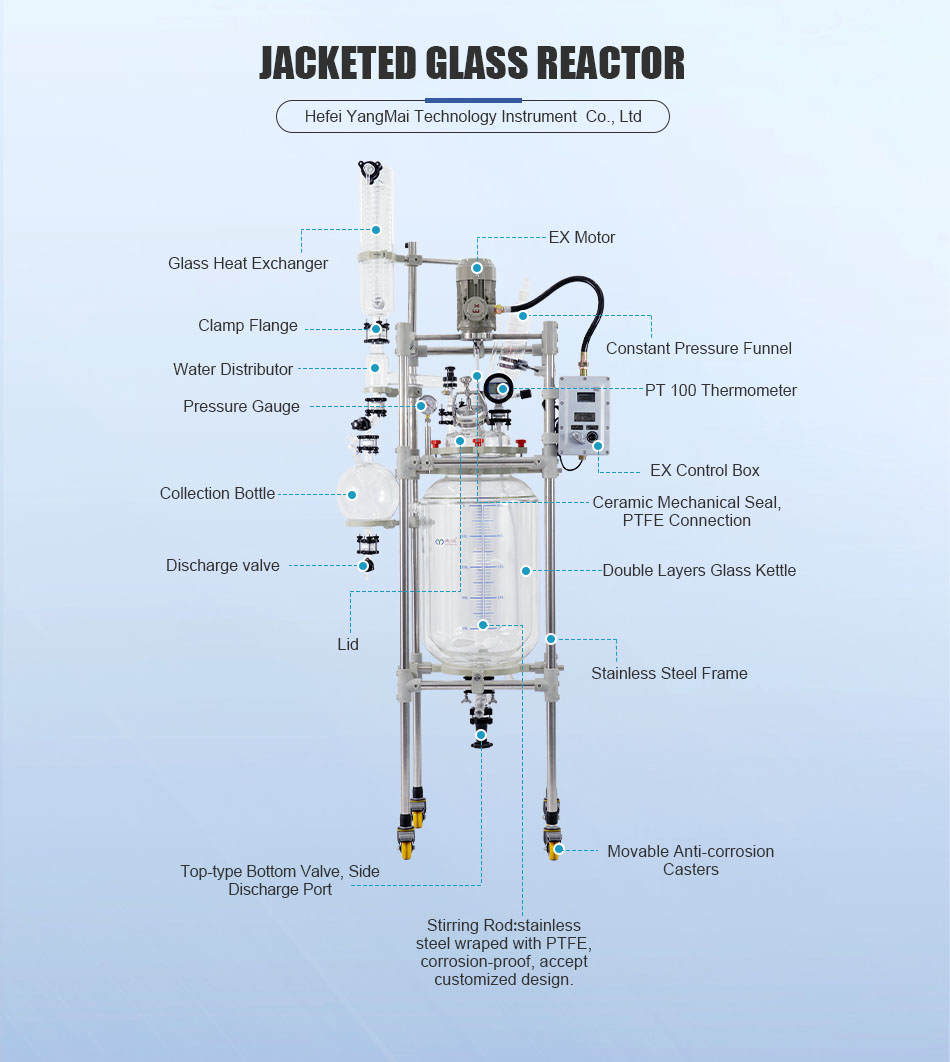

The 150L Jacketed Glass Reactor by Hefei Yangmai Technology Instrument Co., Ltd. is a large-capacity, industrial-grade solution designed for pilot-scale synthesis, solvent recovery, and temperature-sensitive chemical processing. Featuring high-strength borosilicate glass and a double-layer jacket for precise thermal control, it ensures safe and visible operation for demanding workflows in pharmaceutical production, fine chemical manufacturing, and botanical extraction. Built for durability and performance, it's ideal for scaling up from lab to pre-production.

|

Model

|

Volume(L) |

Motor power(w) |

Vaccum degree(Mpa) |

Speed

(Ram)

|

Torque

(Ncm)

|

Power supply |

Size(Cm) |

| YMGR-01 |

1 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-02 |

2 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-05EX |

5 |

180 |

0.096 |

50~600 |

44 |

220V/50HZ |

45*45*110 |

| YMGR-10EX |

10 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*120 |

| YMGR-20EX |

20 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*145 |

| YMGR-30EX |

30 |

180 |

0.096 |

50~600 |

210 |

220V/50HZ |

50*50*160 |

| YMGR-50EX |

50 |

180 |

0.096 |

50~600 |

300 |

220V/50HZ |

60*60*180 |

| YMGR-100EX |

100 |

370 |

0.096 |

50~600 |

400 |

220V/50HZ |

70*70*260 |

| YMGR-150EX |

150 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

85*85*290 |

| YMGR-200EX |

200 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

90*90*300 |

1.Explosion-Proof Safety for Flammable & Volatile Chemicals

Equipped with certified explosion-proof motors and electrical components, ensuring safe operation in environments involving solvents like ethanol, hexane, and acetone.

2.Large-Scale Reaction Capacity

The 150L volume supports pilot-scale and small-batch production, ideal for precious metal purification, nitric acid distillation, and botanical extraction.

3.Double-Layer Borosilicate Glass for Maximum Visibility & Resistance

Durable, high-transparency borosilicate glass offers excellent chemical resistance and full visual monitoring of complex reactions.

4.Precise Thermal and Vacuum Control

The jacketed design allows for wide-range temperature control (-80°C to 250°C), compatible with recirculating chillers and vacuum pumps for efficient solvent recovery and controlled reactions.

5.Stable Operation with Heavy-Duty Frame & Sealing System

Built with an industrial-grade support frame, corrosion-resistant parts, and reliable sealing to handle continuous operation and pressure fluctuations.

6.Ideal for Industrial & R&D Use

Suitable for chemical production, pharmaceutical synthesis, and solvent recycling in explosion-hazard environments such as chemical plants, extraction labs, and metal refining facilities.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.