The 1L Desktop Jacketed Glass Reactor from Hefei Yangmai Technology Instrument Co., Ltd. is a compact, space-saving solution ideal for benchtop chemical synthesis, crystallization, and solvent evaporation. Featuring a double-layer borosilicate glass design, it allows precise temperature control from -80°C to 250°C using external heating or cooling circulation. This reactor is perfect for laboratory-scale research in pharmaceuticals, universities, and specialty chemical development, offering excellent visibility, chemical resistance, and easy integration into small lab spaces.

|

Model

|

Volume(L) |

Motor power(w) |

Vaccum degree(Mpa) |

Speed

(Ram)

|

Torque

(Ncm)

|

Power supply |

Size(Cm) |

| YMGR-01 |

1 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-02 |

2 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-05EX |

5 |

180 |

0.096 |

50~600 |

44 |

220V/50HZ |

45*45*110 |

| YMGR-10EX |

10 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*120 |

| YMGR-20EX |

20 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*145 |

| YMGR-30EX |

30 |

180 |

0.096 |

50~600 |

210 |

220V/50HZ |

50*50*160 |

| YMGR-50EX |

50 |

180 |

0.096 |

50~600 |

300 |

220V/50HZ |

60*60*180 |

| YMGR-100EX |

100 |

370 |

0.096 |

50~600 |

400 |

220V/50HZ |

70*70*260 |

| YMGR-150EX |

150 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

85*85*290 |

| YMGR-200EX |

200 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

90*90*300 |

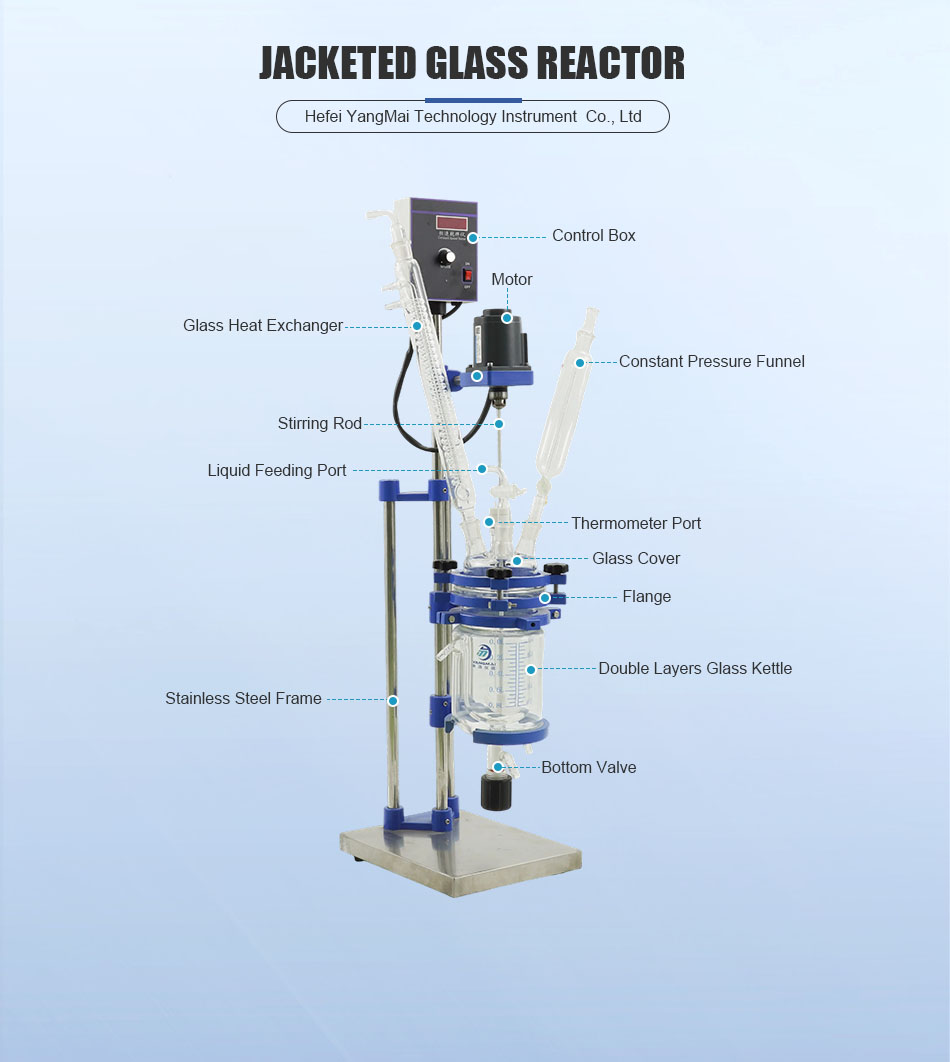

1.High-Purity borosilicate glass construction,acid and alkali resistant, high temperature resistant

2.Dual-Layer precision jacket design,the integrated outer jacket enables efficient thermal fluid circulation.

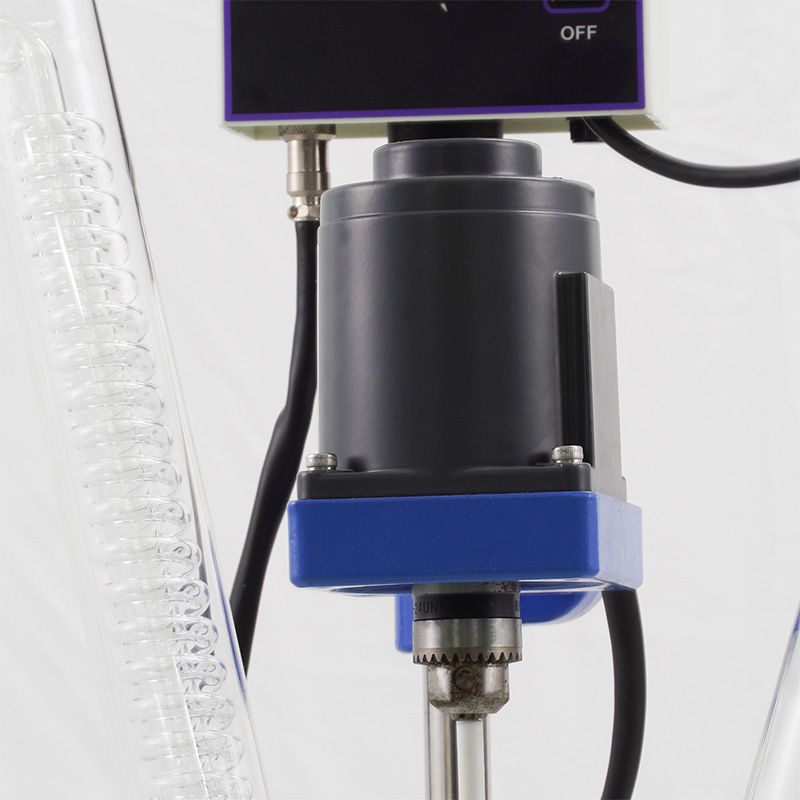

3.PTFE + ceramic mechanical sealing system,corrosion-resistant seal that supports long-term vacuum operation without leakage.

4.Explosion-proof motor and explosion-proof control box,more safe.

5.Customized design accepted.Reactors can be tailored with custom , valve types, stirring paddles, ports,and accessories.

6.Industrial-grade stainless steel frame with and corrosion resistant heavy-duty locking casters, enabling easy movement and secure operation in dynamic lab environments.

7.Advanced Temperature Sensing Accuracy

8.No Dead angle discharge design, reducing material waste and simplifying cleaning between batches.

9.Wide compatibility with auxiliary systems.Seamlessly integrates with chillers, heaters, vacuum pumps,PH meter,ultrasound and so on.

1.Precision Control for Micro-Scale Reactions

Designed for accurate heating and cooling of small-volume reactions, perfect for R&D, formulation testing, and compound screening.

2.High-Quality Borosilicate Glass Construction

Offers exceptional chemical resistance, thermal stability, and full transparency for real-time observation of reaction progress.

3.Efficient Jacketed Thermal Design

Double-layer jacket allows seamless integration with circulators for temperature control between -80°C and +250°C.

4.Compact, Space-Saving Structure

Ideal for benchtop applications in labs with limited space while maintaining all core reaction functions.

5.Versatile Application Range

Suitable for organic synthesis, crystallization, distillation, and solvent recovery involving chemicals like ethanol, methanol, or acids.

6.User-Friendly Operation & Customization

Comes with adjustable stirring, digital displays, and optional vacuum components, enabling easy adaptation for specific research needs.

7.Trusted for Laboratory Innovation

Built by Yangmai Tech with a focus on safety, reliability, and research efficiency in pharmaceutical, academic, and chemical sectors.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.