What Are Glass Reactors Used For?

Aug 21, 2025

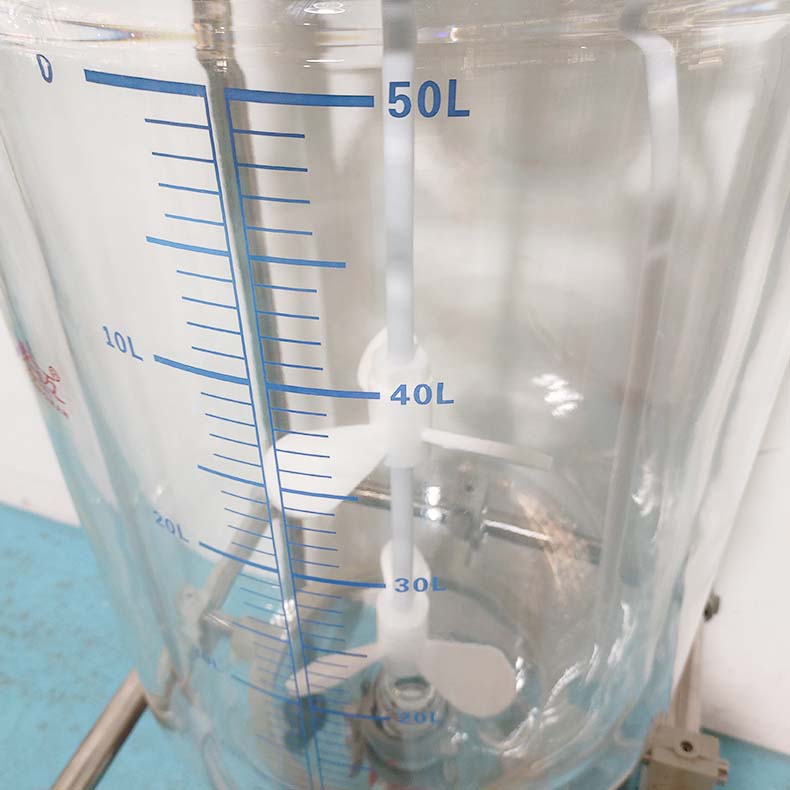

Glass reactors are indispensable equipment in modern laboratories and pilot plants, providing a transparent and controlled environment for a wide range of chemical and pharmaceutical processes. Built from high borosilicate glass, they offer exceptional chemical resistance, excellent visibility, and reliable thermal performance, making them a preferred choice for researchers and production facilities worldwide.

Key Applications of Glass Reactors

1. Chemical Synthesis and Reaction EngineeringGlass reactors are widely used for controlled chemical synthesis, including crystallization, hydrogenation, polymerization, and catalytic reactions. The transparent body allows direct monitoring of reaction changes, ensuring precision and reproducibility.

2. Pharmaceutical and Biotechnology ResearchIn the pharmaceutical industry, glass reactors support the synthesis of APIs, intermediates, and fine chemicals. Their inert material ensures that reactions remain free from contamination, which is critical for drug discovery and biotechnological innovation.

3. Distillation, Extraction, and PurificationWhen paired with condensers, vacuum pumps, and heating/cooling circulators, glass reactors can be transformed into complete systems for fractional distillation, solvent recovery, essential oil extraction, and purification of sensitive compounds.

4. Material Science and Polymer DevelopmentUniversities and industrial R&D centers rely on glass reactors to explore new polymers, nanomaterials, and resins. Their ability to operate under vacuum or pressure makes them highly adaptable for advanced material research.

5. Pilot Production and Scale-Up StudiesGlass reactors bridge the gap between laboratory experiments and full-scale industrial production. They are commonly used for process optimization, feasibility studies, and small-batch pilot runs.

Why Choose Yangmai Glass Reactors?

Premium Borosilicate Glass Construction – High durability, thermal stability, and resistance to strong acids and solvents.

Customizable Solutions – Options include single-layer, double-layer, and explosion-proof designs to match different experimental needs.

Integrated Laboratory Systems – Easily connected with high & low temperature circulators, vacuum filtration units, and distillation columns.

Global Trust – Widely adopted by pharmaceutical companies, chemical plants, and research institutes for reliable performance and long service life.

Conclusion

Glass reactors are more than just laboratory reactors — they are versatile platforms for innovation, discovery, and industrial development. From small-scale research to pilot plant production, they play a vital role in ensuring safe, efficient, and reproducible processes.

At Yangmai Glass Reator Insturment, we are committed to delivering high-quality glass reactors and complete laboratory solutions that empower researchers and manufacturers around the world.

👉 Reach out to Yangmai today and explore how our advanced glass reactor systems can accelerate your research and production goals.