How to Select the Right Glass Reactor Capacity (1L–200L)

Aug 28, 2025

Glass reactors play a vital role in chemical research, pharmaceutical development, and industrial production. With capacities ranging from 1L laboratory scale to 200L industrial systems, selecting the right size is essential for efficiency, safety, and cost control.

Why Reactor Capacity Matters:

The reactor volume directly affects reaction efficiency, heating and cooling performance, solvent use, and safety.

a. Too small → frequent batching, wasted time.

b. Too large → unnecessary energy consumption and higher costs.

Finding the right balance ensures smooth, reliable experiments and production.

Glass Reactor Capacity Guide

🔹1L–5L Glass Reactors

Applications: Lab R&D, chemistry teaching, small-scale synthesis.

Best for: Trial reactions, catalyst screening, formulation tests.

Advantages: Low cost, easy operation, perfect for students and researchers.

🔹10L–20L Glass Reactors

Applications: Advanced lab studies, pilot testing.

Best for: Process optimization, crystallization, solvent recovery.

Advantages: Great balance between research flexibility and output.

🔹 30L–50L Glass Reactors

Applications: Pilot plant work, scale-up synthesis.

Best for: Transition from lab to production.

Advantages: Handles multi-step chemistry, suitable for pharmaceutical intermediates.

🔹 80L–100L Glass Reactors

Applications: Pre-production trials, semi-industrial work.

Best for: Fine chemicals, botanical extraction, complex reactions.

Advantages: Large batch size, stable control, vacuum-compatible.

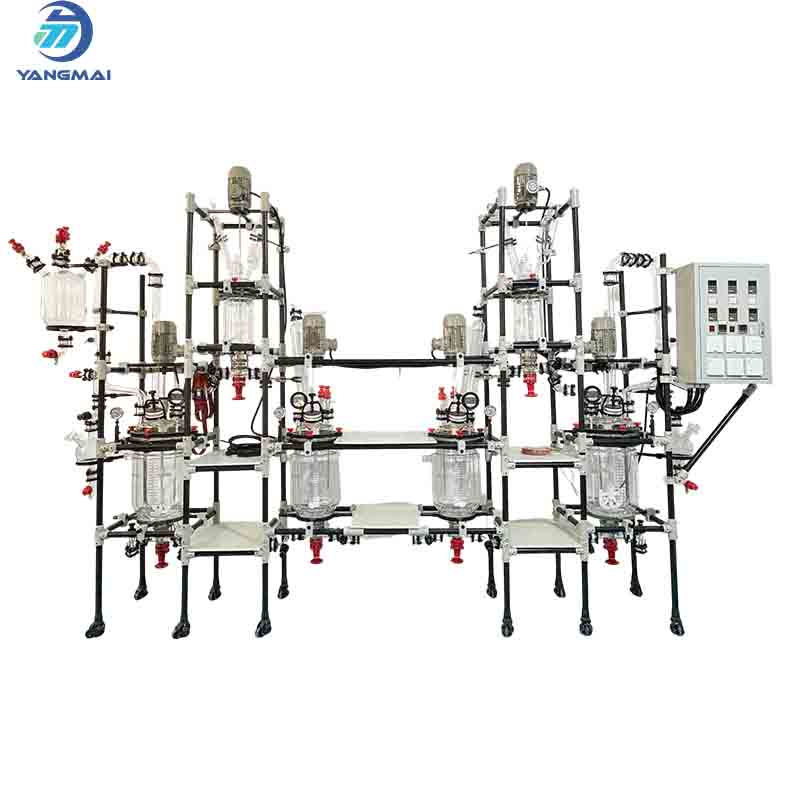

🔹 150L–200L Glass Reactors

Applications: Industrial manufacturing, continuous processing.

Best for: High-volume synthesis, CBD extraction, pharma production.

Advantages: Heavy-duty design, explosion-proof options, efficient for mass production.

Key Factors to Consider

Reaction Type – Heating, cooling, crystallization, or distillation.

Material Cost – Minimize losses with smaller volumes in early trials.

Scale-Up Plan – Start small and expand to pilot or industrial reactors.

Space & Utilities – Consider lab space, cooling water, and power needs.

Safety Requirements – Larger reactors may require explosion-proof motors and reinforced supports.

Conclusion

Choosing the right glass reactor capacity (1L–200L) depends on your project stage:

1–5L → research and teaching.

10–50L → pilot testing and process optimization.

80–200L → pre-production and industrial manufacturing.

With the right size, you’ll achieve better efficiency, safer operation, and cost-effective results for your chemical processes.