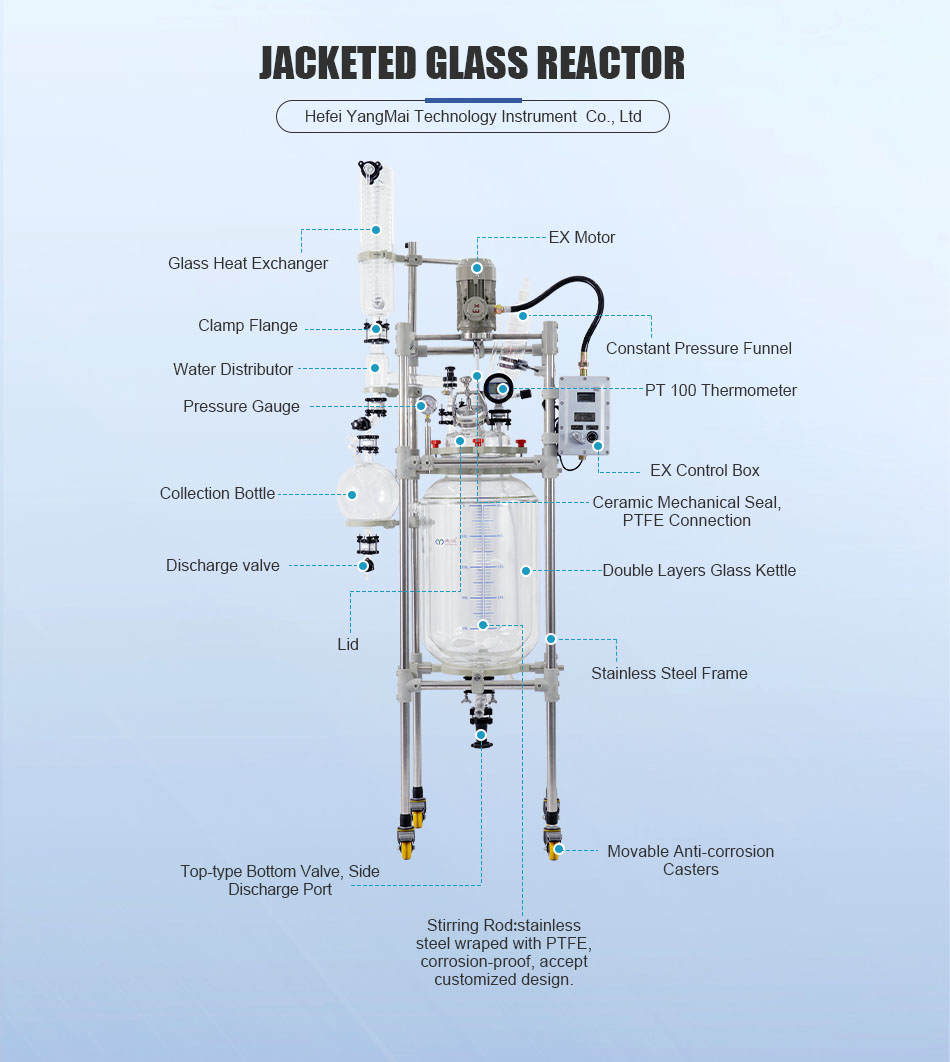

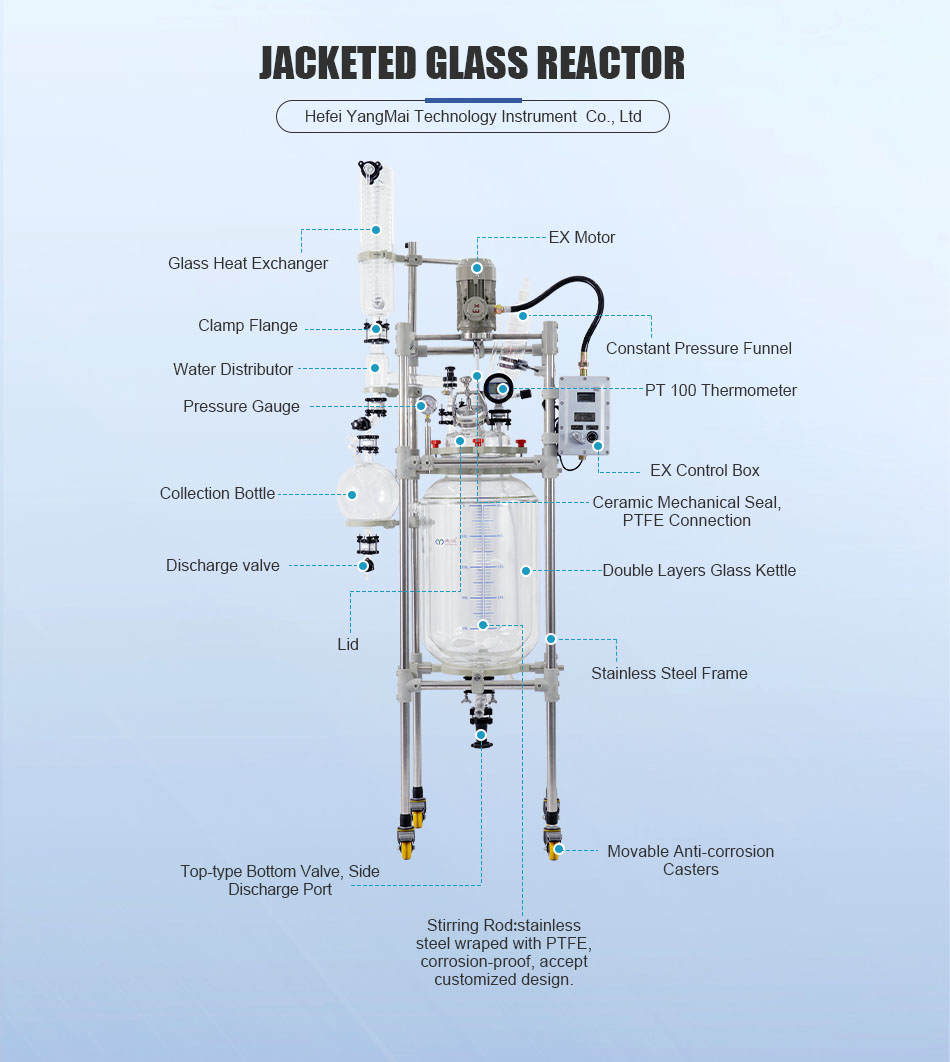

The 10L Jacketed Glass Reactor from Hefei Yangmai Technology Instrument Co., Ltd. is built for high-precision chemical processes such as sulfonation, diazotization, and small-batch polymer synthesis. With a double-layer borosilicate glass design, it provides excellent visibility, chemical resistance, and precise temperature control from -80°C to 250°C. Ideal for research labs and specialty chemical manufacturers, this compact reactor supports efficient mixing, heating, and cooling, making it a reliable tool for complex reaction development and solvent recovery in advanced R&D environments.

|

Model

|

Volume(L) |

Motor power(w) |

Vaccum degree(Mpa) |

Speed

(Ram)

|

Torque

(Ncm)

|

Power supply |

Size(Cm) |

| YMGR-01 |

1 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-02 |

2 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-05EX |

5 |

180 |

0.096 |

50~600 |

44 |

220V/50HZ |

45*45*110 |

| YMGR-10EX |

10 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*120 |

| YMGR-20EX |

20 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*145 |

| YMGR-30EX |

30 |

180 |

0.096 |

50~600 |

210 |

220V/50HZ |

50*50*160 |

| YMGR-50EX |

50 |

180 |

0.096 |

50~600 |

300 |

220V/50HZ |

60*60*180 |

| YMGR-100EX |

100 |

370 |

0.096 |

50~600 |

400 |

220V/50HZ |

70*70*260 |

| YMGR-150EX |

150 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

85*85*290 |

| YMGR-200EX |

200 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

90*90*300 |

-

1. Jacketed Glass Kettle: A double-layered design allows for precise temperature control by circulating heating or cooling fluids through the jacket.

-

2. Efficient Stirring System: A powerful motor and an adjustable stirring paddle ensure thorough and uniform mixing of reactants.

-

3. Vacuum/Pressure Capability: The sealed design supports reactions and distillation under vacuum or slight positive pressure.

-

4. Equipped with Condenser: The unit can be connected to a high-efficiency condenser for solvent reflux, distillation, and vapor condensation.

-

5. Lid with Feeding Funnel: The lid includes a funnel or hopper, making it easy to add solid or liquid materials during the reaction without opening the lid.

-

6. Bottom Discharge Valve: A convenient valve at the bottom allows for quick and clean removal of products or waste liquids.

-

7. High-Quality Glass: Constructed from high borosilicate glass, it offers excellent resistance to chemical corrosion, high temperatures, and thermal shock.

-

8. Modular Design: The stable and modular frame allows for easy assembly, disassembly, and maintenance.

FAQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.