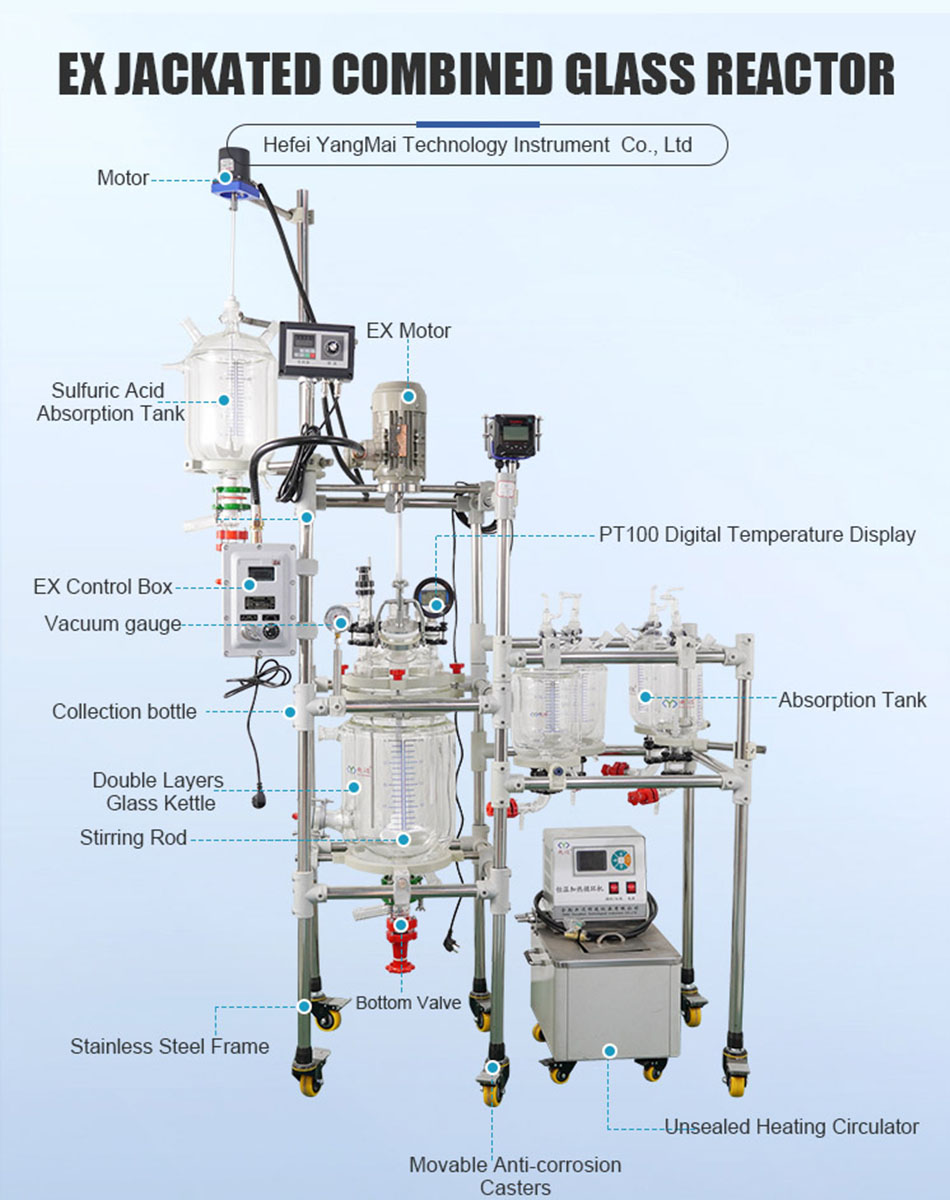

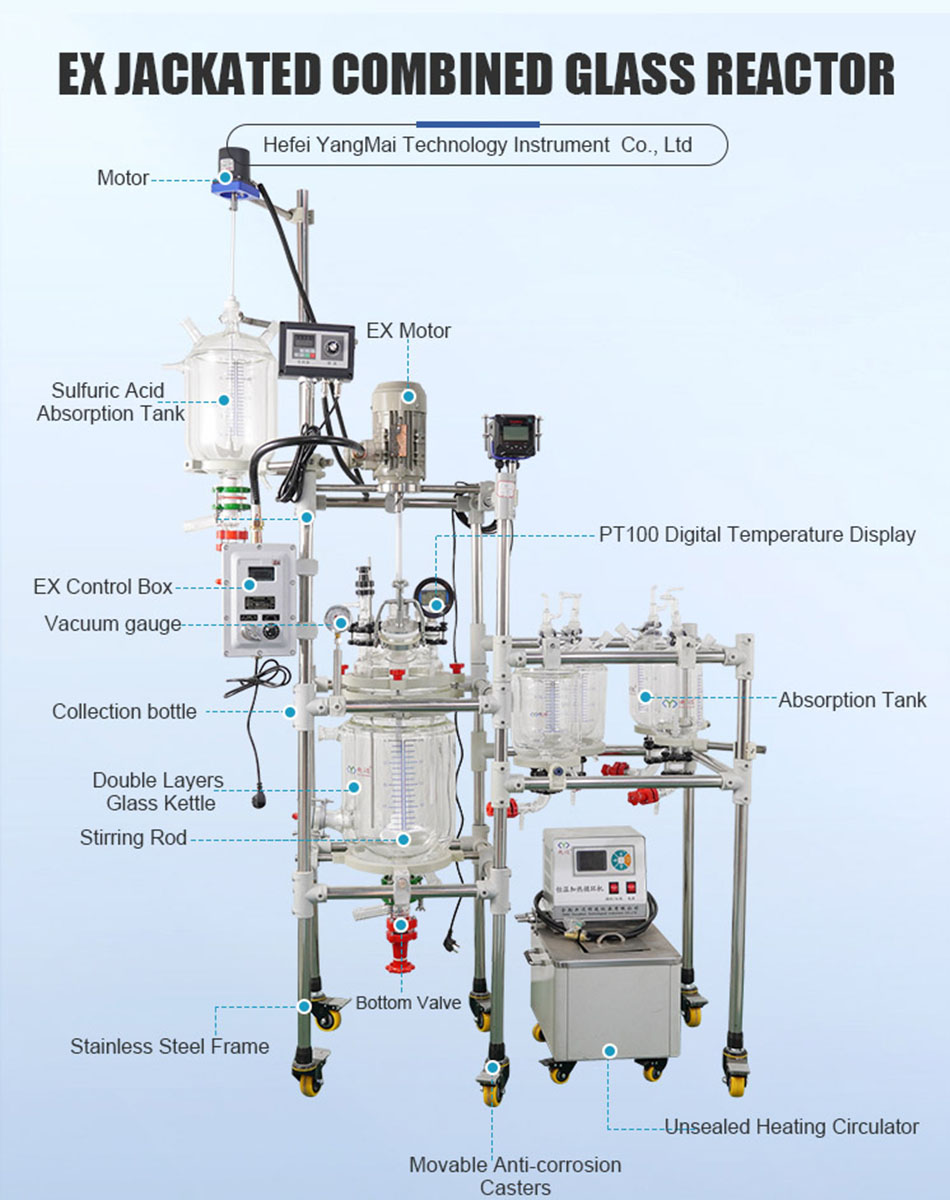

The 10L complete jacketed glass reactor system by Hefei Yangmai Technology Instrument Co., Ltd. is specifically designed for ruthenium distillation processes based on oxidative volatilization. The system supports controlled conversion of ruthenium into volatile RuO₄, enabling efficient separation and recovery under precisely regulated temperature conditions.

|

Model

|

Volume(L) |

Motor power(w) |

Vaccum degree(Mpa) |

Speed

(Ram)

|

Torque

(Ncm)

|

Power supply |

Size(Cm) |

| YMGR-01 |

1 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-02 |

2 |

40 |

0.096 |

50~600 |

30 |

220V/50HZ |

32*35*80 |

| YMGR-05EX |

5 |

180 |

0.096 |

50~600 |

44 |

220V/50HZ |

45*45*110 |

| YMGR-10EX |

10 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*120 |

| YMGR-20EX |

20 |

180 |

0.096 |

50~600 |

162 |

220V/50HZ |

50*50*145 |

| YMGR-30EX |

30 |

180 |

0.096 |

50~600 |

210 |

220V/50HZ |

50*50*160 |

| YMGR-50EX |

50 |

180 |

0.096 |

50~600 |

300 |

220V/50HZ |

60*60*180 |

| YMGR-100EX |

100 |

370 |

0.096 |

50~600 |

400 |

220V/50HZ |

70*70*260 |

| YMGR-150EX |

150 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

85*85*290 |

| YMGR-200EX |

200 |

750 |

0.096 |

50~600 |

500 |

220V/50HZ |

90*90*300 |

1.Purpose-Built for Ruthenium Distillation

Designed specifically for oxidative volatilization processes where ruthenium is converted into volatile RuO₄ for controlled separation and recovery.

2. Complete Jacketed Glass Reactor System

Supplied as a full system including reactor vessel, jacketed heating interface, and connection ports for condenser and absorption units.

3. High Borosilicate Glass Construction

Manufactured from chemical-resistant borosilicate glass, suitable for strong oxidizing agents and acidic media used in precious metal refining.

4. Precise Temperature Control Capability

Double jacket design supports uniform heating or cooling, ensuring stable reaction conditions during oxidation and distillation stages.

5. Compatible with RuO₄ Capture Systems

Designed for easy integration with glass condensers and absorption vessels for efficient volatile metal capture.

FAQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.