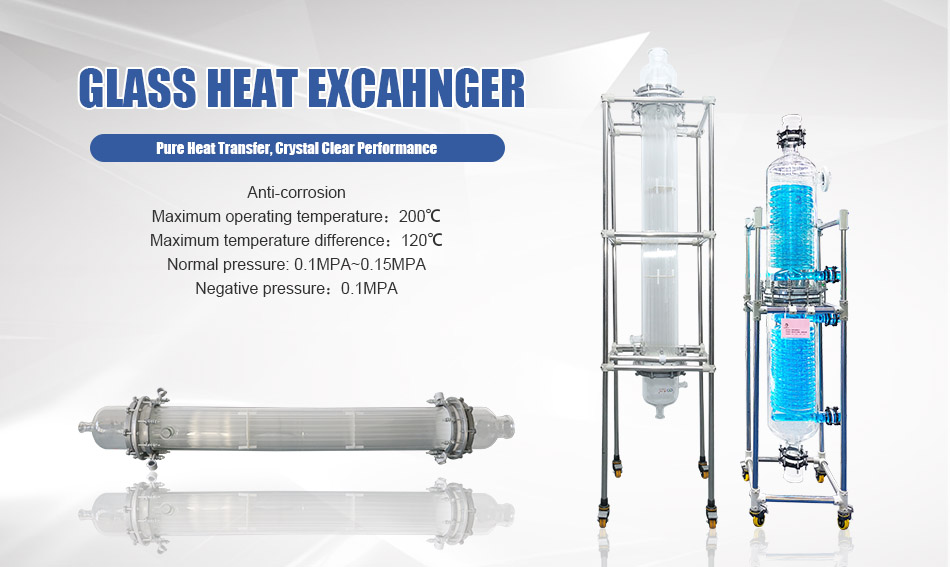

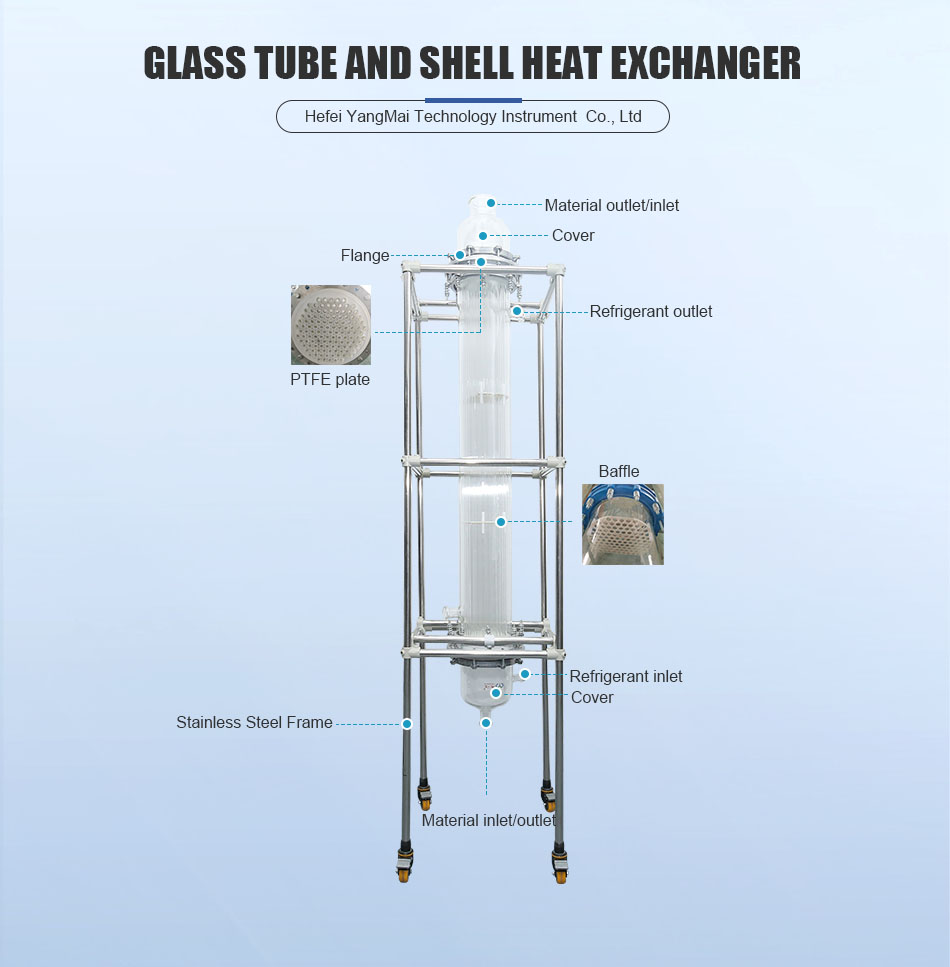

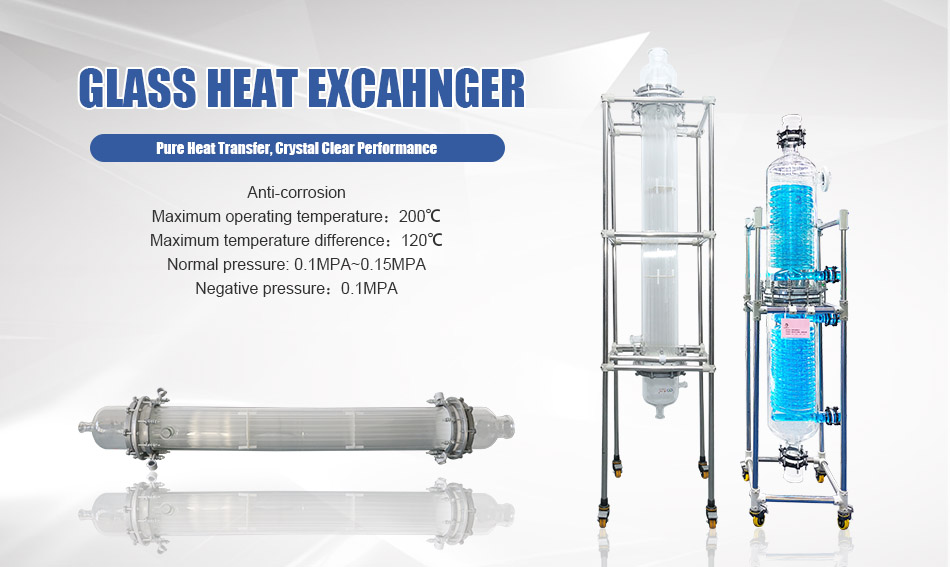

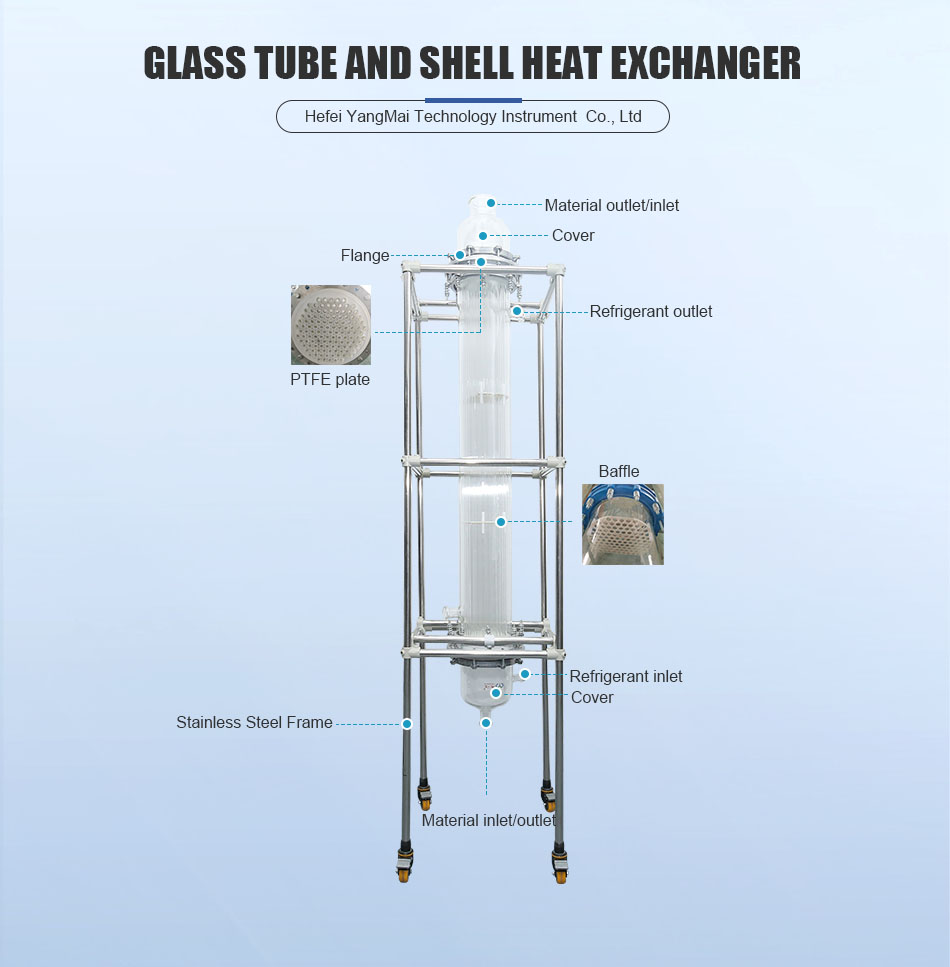

The Glass Tube and Shell Heat Exchanger from Hefei Yangmai Technology Instrument Co., Ltd is engineered for efficient heat transfer in corrosive chemical environments such as sulfuric acid cooling, solvent recovery, and acid-base heat exchange systems. Built with high-purity borosilicate glass, it ensures excellent chemical resistance, thermal stability, and visual process monitoring—making it ideal for pharmaceutical, chemical, and laboratory applications requiring both performance and purity.

Application:

Corrosion resistance includes all organic and inorganic media (except hydrofluoric acid and fluoride, hot phosphoric acid and concentrated alkali at high temperatures).

Allowable operating temperature on the shell tube side: ≤150°C

Allowable working pressure on the shell side of each type of exchanger :

Allowed working pressure on the shell side: 3m², 4m²: ≤0.15MPa;

5m², 6m², 10m², 12m², 16m², 20m², 25m²: ≤0.1MPa;

Allowable working pressure of the pipe: 3m², 4m²: ≤0.1MPa;

5m², 6m², 10m², 12m², 16m², 20m², 25m²: ≤0.1MPa;

Pressure difference between shell and pipe side: ≤0.25MPa

Maximum temperature difference: ≤120℃

Fluid flow resistance on the tube side: (take 5 square meters as an example)

△PH2O=0.10275H2O·m(Vt=1.9906L/S)

1. Strong corrosion resistance

Made from high-purity borosilicate glass, it resists strong acids, bases, and solvents—ideal for highly corrosive environments like sulfuric acid and nitric acid processes.

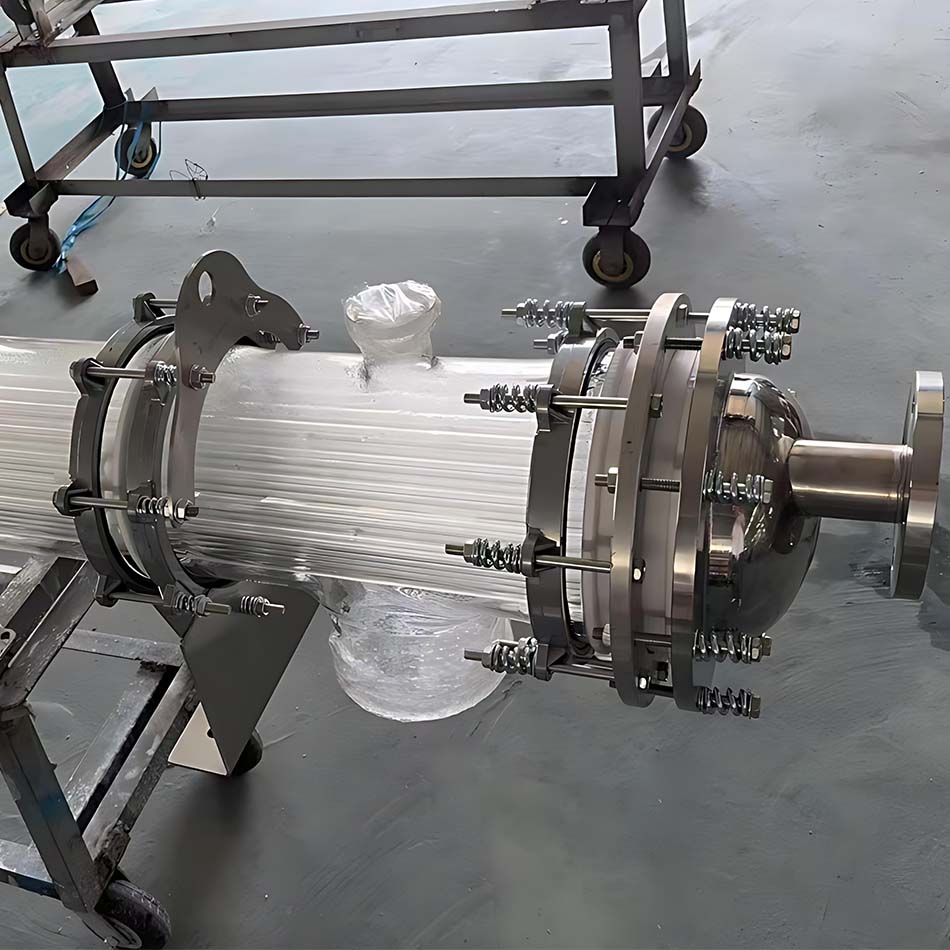

2. Excellent heat transfer performance

The increase in the length of the tubes prolongs the heat exchange time accordingly. Since the material can pass through the shell, the material will be completely emptied when it is installed horizontally.

3. Minimal pressure loss

The material can flow through the tube side or the shell side, which reduces the material's resistance and reduces the system's pressure loss.At the same time, large-diameter multi-channels also effectively reduce material evaporation and flow resistance

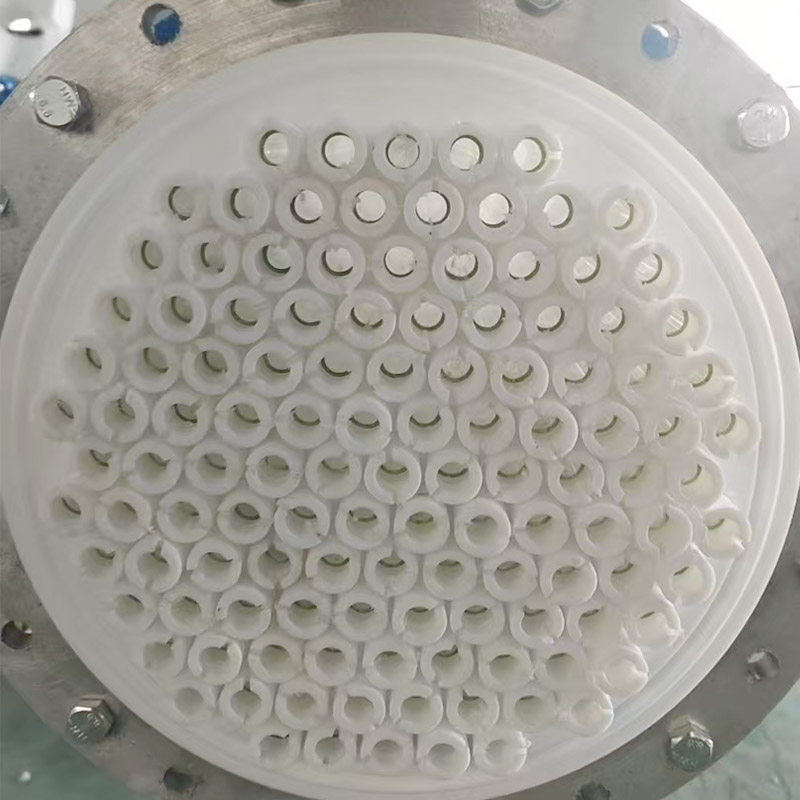

4. Good sealing

The glass heat exchange tube sealing material adopts PTFE sealing, which improves the reliability of the heat exchange tube sealing point and prolongs the life of the equipment under high temperature corrosion conditions.

5. Easy to maintain and reinstall the inner tube

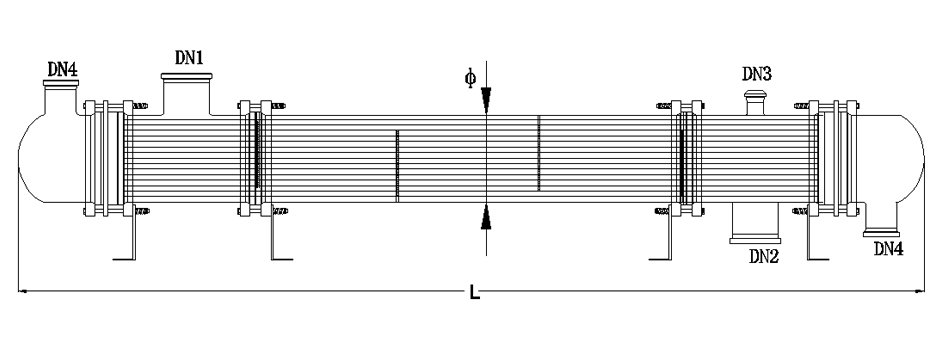

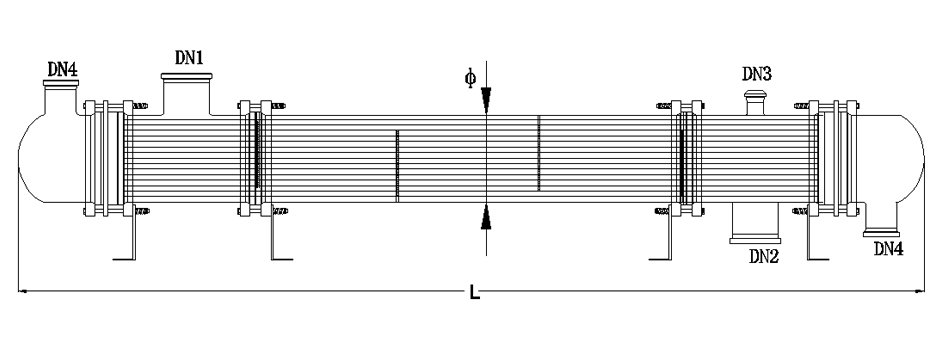

| Heat exchange area(㎡) |

φ(mm) |

DN1(mm) |

DN2(mm) |

DN3(mm) |

DN4(mm) |

L(mm) |

| 1 |

180 |

25~100 |

25~100 |

25~100 |

25~100 |

900 |

| 2 |

180 |

1400 |

| 3 |

180 |

1900 |

| 4 |

230 |

1900 |

| 5 |

230 |

2200 |

| 6 |

230 |

2500 |

| 8 |

300 |

2100 |

| 10 |

300 |

2500 |

| 12 |

315 |

50~230 |

50~230 |

50~150 |

50~150 |

2750 |

| 15 |

315 |

3400 |

| 20 |

315 |

4000 |

| 25 |

315 |

4500 |

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.