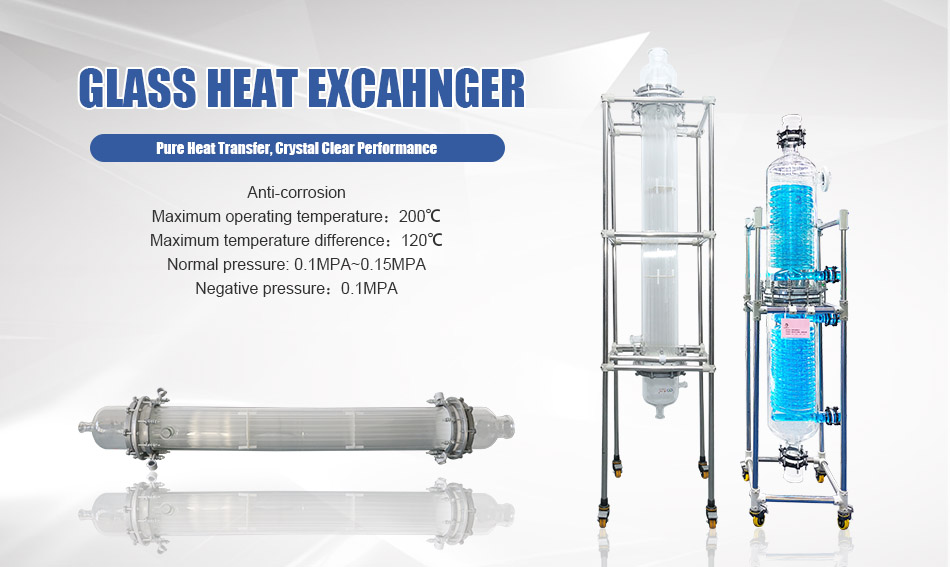

The Glass Coil Heat Exchanger from Hefei Yangmai Technology Instrument Co., Ltd is specifically engineered for efficient heat exchange in corrosive and high-purity environments. Constructed from durable borosilicate glass with precision-formed internal coils, it ensures optimal thermal transfer while withstanding aggressive chemicals like acids and solvents. Ideal for applications such as solvent condensation, acid recovery, and temperature regulation in distillation systems, it delivers reliable, contamination-free performance in both laboratory and industrial settings.

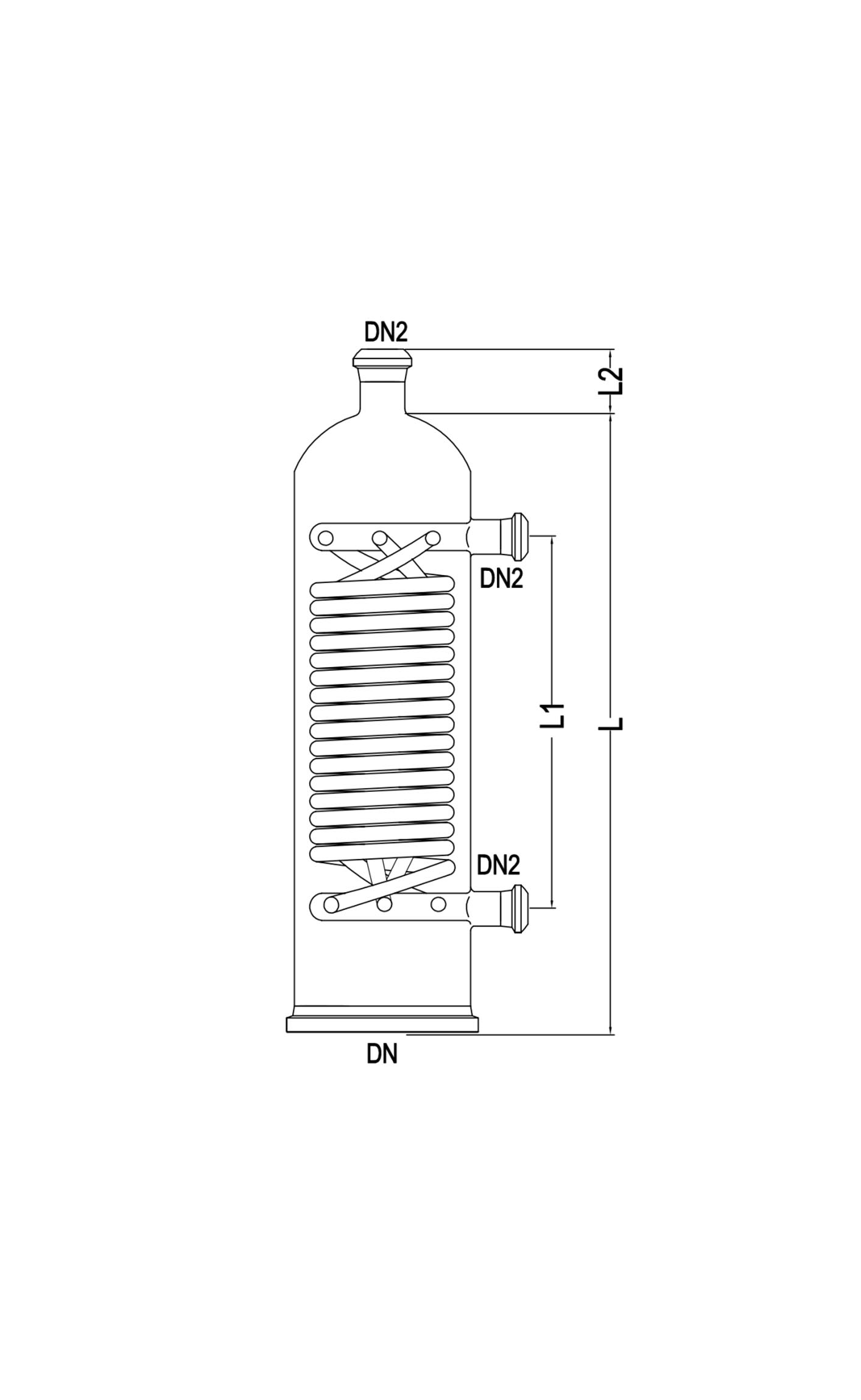

| Heat Exchanger Area(㎡)2 |

DN

(mm)

|

DN1

(mm)

|

DN2

(mm)

|

L

(mm)

|

L1

(mm)

|

L2

(mm)

|

| 0.3 |

100 |

15 |

25 |

450 |

300 |

65 |

| 100 |

15 |

40 |

450 |

300 |

80 |

| 100 |

15 |

50 |

450 |

300 |

85 |

| 100 |

15 |

80 |

450 |

300 |

100 |

| 0.6 |

150 |

25 |

25 |

525 |

355 |

65 |

| 150 |

25 |

40 |

525 |

355 |

80 |

| 150 |

25 |

50 |

525 |

355 |

85 |

| 150 |

25 |

80 |

525 |

355 |

100 |

| 150 |

25 |

100 |

525 |

355 |

100 |

| 1 |

φ180 |

25 |

25 |

620 |

430 |

65 |

| φ180 |

25 |

25 |

620 |

430 |

80 |

| φ180 |

25 |

25 |

620 |

430 |

85 |

| φ180 |

25 |

25 |

620 |

430 |

100 |

| φ180 |

25 |

25 |

620 |

430 |

100 |

| 1.5 |

φ230 |

40 |

40 |

725 |

485 |

65 |

| φ230 |

40 |

40 |

725 |

485 |

80 |

| φ230 |

40 |

40 |

725 |

485 |

85 |

| φ230 |

40 |

40 |

725 |

485 |

100 |

| φ230 |

40 |

40 |

725 |

485 |

100 |

| 2.5 |

300 |

50 |

50 |

725 |

485 |

85 |

| 300 |

50 |

50 |

725 |

485 |

100 |

| 300 |

50 |

50 |

725 |

485 |

100 |

| 3 |

300 |

50 |

50 |

830 |

585 |

90 |

| 300 |

50 |

50 |

830 |

585 |

100 |

| 300 |

50 |

50 |

830 |

585 |

100 |

1.Excellent Acid Resistance

Made from high-purity borosilicate glass, it resists strong oxidizers like nitric acid without corrosion or contamination.

2.Efficient Heat Transfer

The internal glass coil design maximizes surface area, enabling fast and uniform thermal exchange in highly reactive environments.

3.High Transparency for Process Monitoring

Clear glass body allows operators to visually monitor flow and reaction behavior during temperature regulation or acid processing.

4.Safe Handling of Corrosive Media

Non-metallic construction eliminates risks of metal contamination, ideal for ultra-pure or highly corrosive chemical workflows.

5.Stable Under Extreme Conditions

Supports high temperatures and pressures while maintaining structural and chemical integrity during continuous operation.

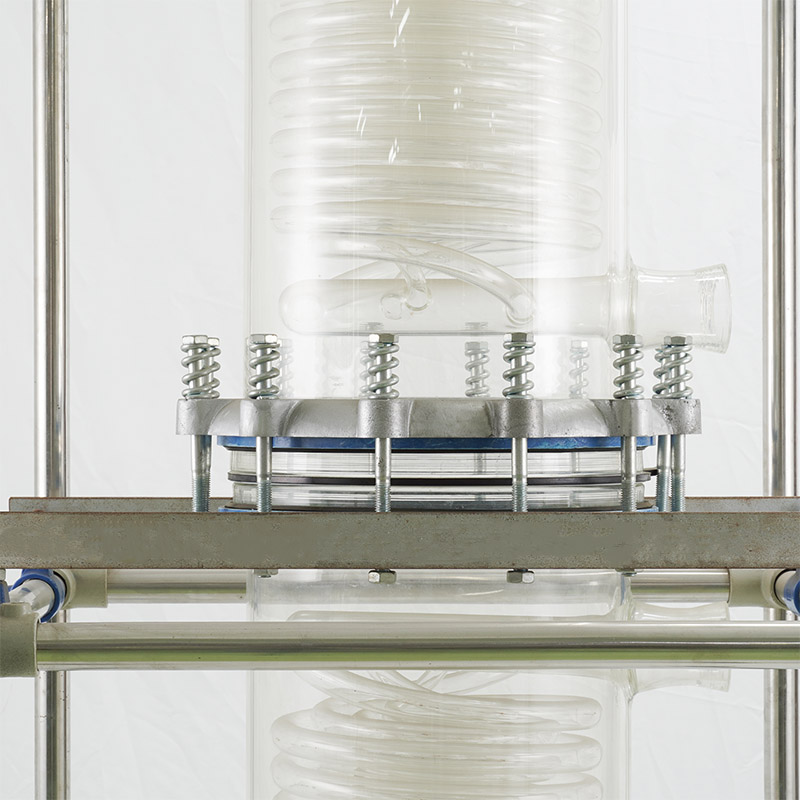

6.Good sealing, no leakage points

The heat exchange tube is directly welded to the shell, with no leakage points between the sleeve and the tube end

7.Flexible assembly

Can be connected in series or in parallel to meet the needs of different heat exchange areas

8.Ideal for Laboratory and Pilot-Scale Use

Perfect for nitric acid purification, cooling loops, or heat recovery systems in chemical synthesis, pharmaceutical production, and materials research.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.