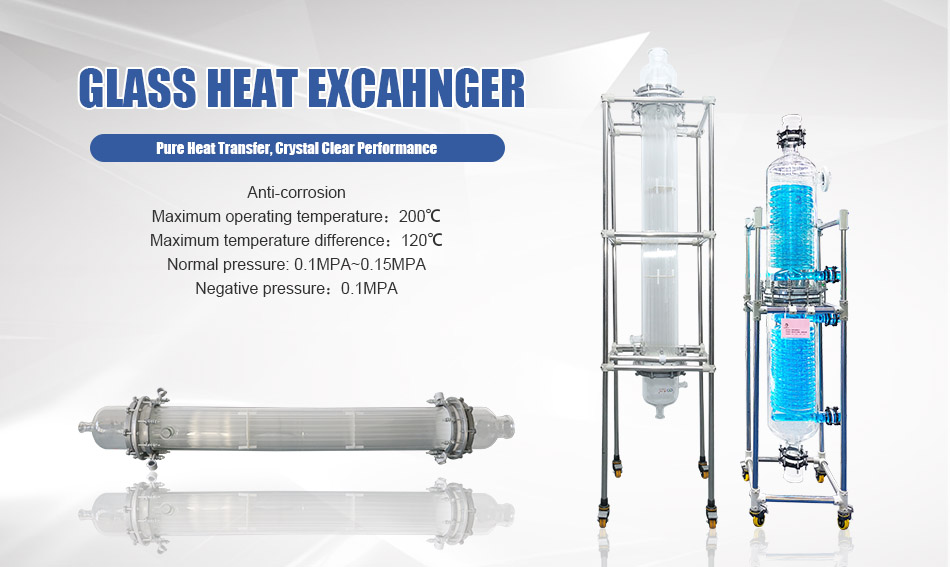

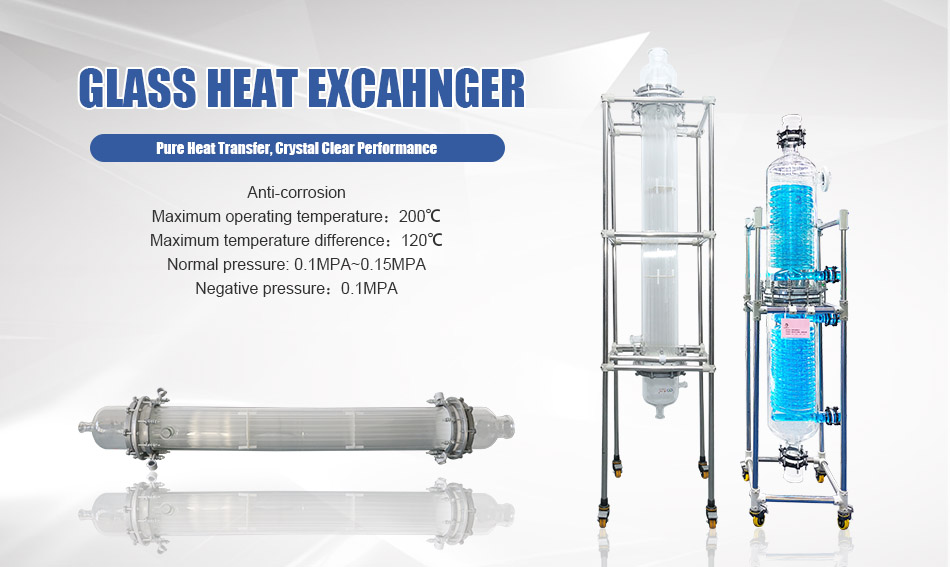

The Glass Coil Heat Exchanger from Hefei Yangmai Technology Instrument Co., Ltd features a spiral borosilicate coil housed in a corrosion-resistant glass shell, delivering targeted heat exchange performance in ultra-clean and chemically aggressive environments. Ideal for acid vapor condensation, closed-loop solvent cooling, and thermal separation systems, it offers unmatched visibility, chemical purity, and control—making it the preferred solution for high-precision cooling in fine chemical, pharmaceutical, and green solvent recovery operations.

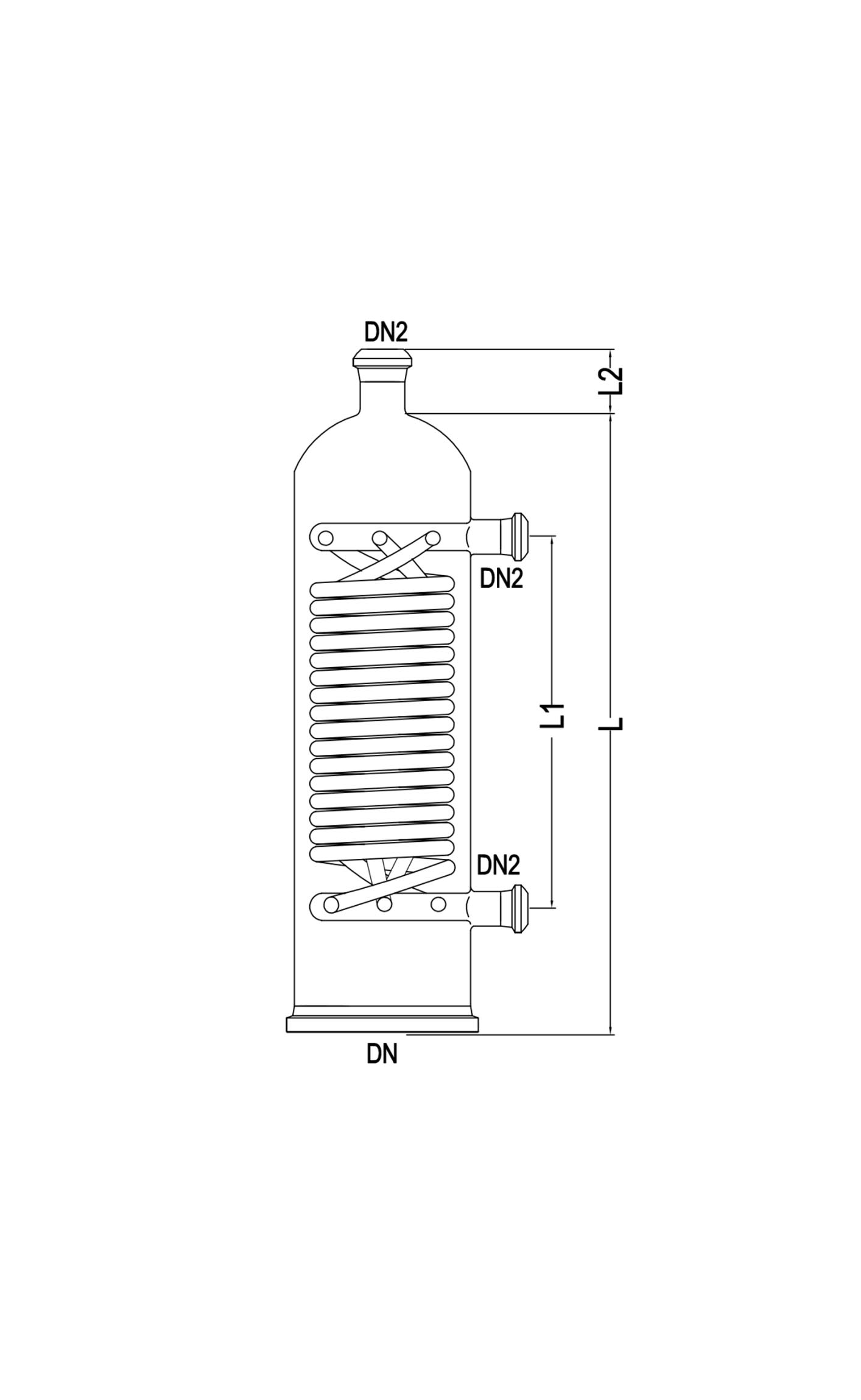

| Heat Exchanger Area(㎡)2 |

DN

(mm)

|

DN1

(mm)

|

DN2

(mm)

|

L

(mm)

|

L1

(mm)

|

L2

(mm)

|

| 0.3 |

100 |

15 |

25 |

450 |

300 |

65 |

| 100 |

15 |

40 |

450 |

300 |

80 |

| 100 |

15 |

50 |

450 |

300 |

85 |

| 100 |

15 |

80 |

450 |

300 |

100 |

| 0.6 |

150 |

25 |

25 |

525 |

355 |

65 |

| 150 |

25 |

40 |

525 |

355 |

80 |

| 150 |

25 |

50 |

525 |

355 |

85 |

| 150 |

25 |

80 |

525 |

355 |

100 |

| 150 |

25 |

100 |

525 |

355 |

100 |

| 1 |

φ180 |

25 |

25 |

620 |

430 |

65 |

| φ180 |

25 |

25 |

620 |

430 |

80 |

| φ180 |

25 |

25 |

620 |

430 |

85 |

| φ180 |

25 |

25 |

620 |

430 |

100 |

| φ180 |

25 |

25 |

620 |

430 |

100 |

| 1.5 |

φ230 |

40 |

40 |

725 |

485 |

65 |

| φ230 |

40 |

40 |

725 |

485 |

80 |

| φ230 |

40 |

40 |

725 |

485 |

85 |

| φ230 |

40 |

40 |

725 |

485 |

100 |

| φ230 |

40 |

40 |

725 |

485 |

100 |

| 2.5 |

300 |

50 |

50 |

725 |

485 |

85 |

| 300 |

50 |

50 |

725 |

485 |

100 |

| 300 |

50 |

50 |

725 |

485 |

100 |

| 3 |

300 |

50 |

50 |

830 |

585 |

90 |

| 300 |

50 |

50 |

830 |

585 |

100 |

| 300 |

50 |

50 |

830 |

585 |

100 |

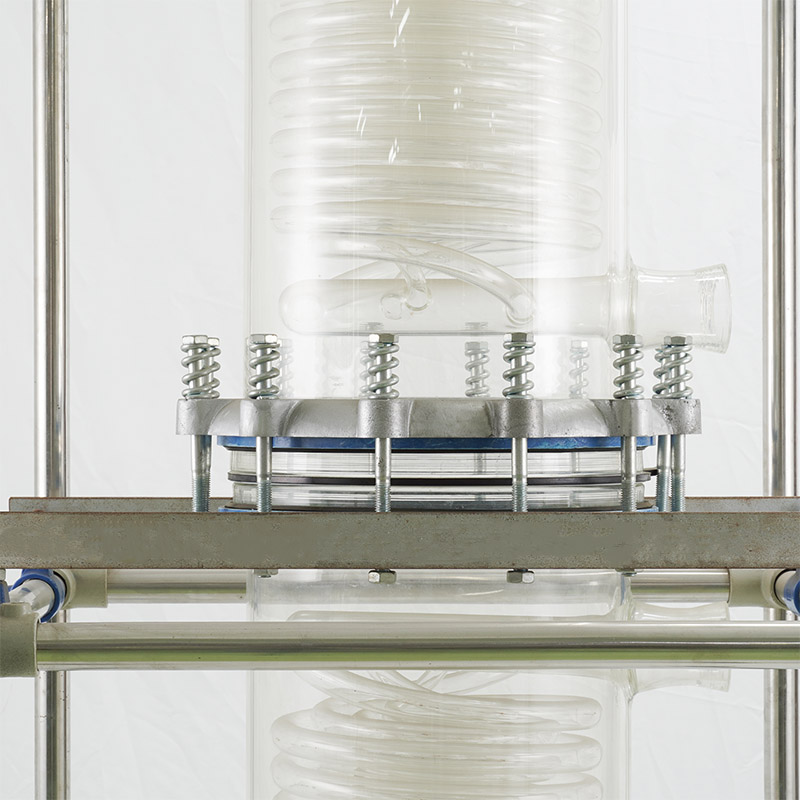

1.Compact Spiral Design for Space Efficiency

The tightly wound coil configuration provides high thermal exchange in a minimal footprint, ideal for fume hoods, mobile reactors, and compact process setups.

2.Non-Disruptive Laminar Flow Performance

Engineered for consistent internal flow patterns, reducing turbulence and promoting stable heat exchange even under variable pressure or vacuum.

3.Cross-Media Compatibility

Compatible with steam, cooling liquids, and aggressive vapors—including acetic acid, formic acid, and organic esters—without degradation or fouling.

4.Thermal Shock Resistance

The coil and shell structure is tested to withstand rapid temperature changes, reducing breakage risk in start-stop or batch process operations.

5.Visual Integrity Check Without Disassembly

The fully transparent shell and coil layout allows for real-time inspection of scaling, fouling, or blockage—supporting preventive maintenance without downtime.

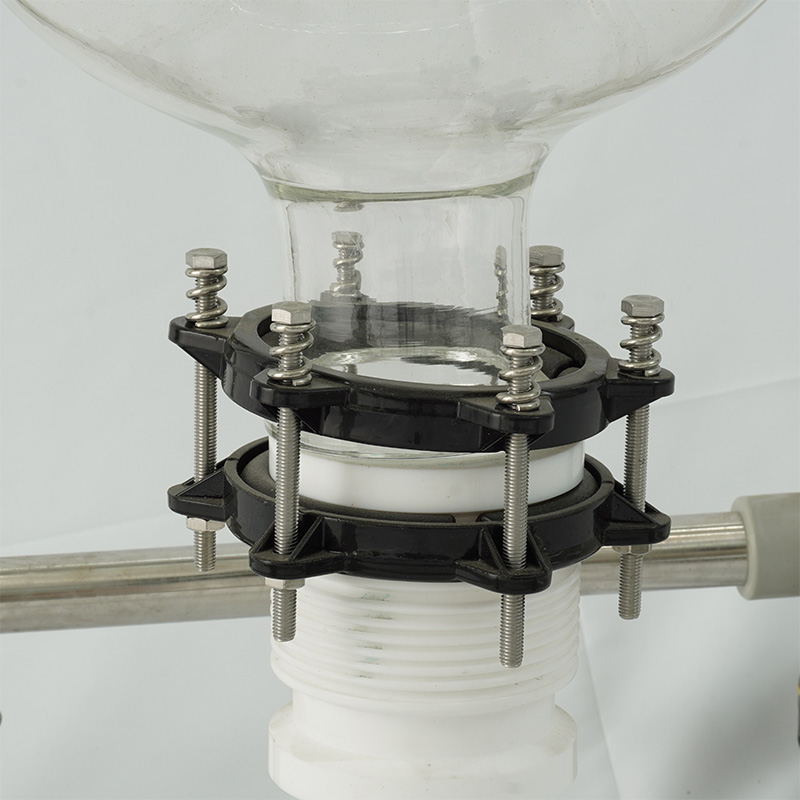

6.Customizable Connection Ports

Available in standard and custom port configurations (flange, threaded, quick-fit) to support integration into diverse process lines.

6.Cleanroom and GMP Compatibility

Non-reactive and easy-to-clean surfaces make it suitable for use in pharmaceutical and high-purity processing environments.

7.Ideal for Closed-Loop Cooling and Condensation Systems

Efficiently recycles thermal energy in solvent recovery, jacketed reactor loops, and distillation condensation with minimal energy loss.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.