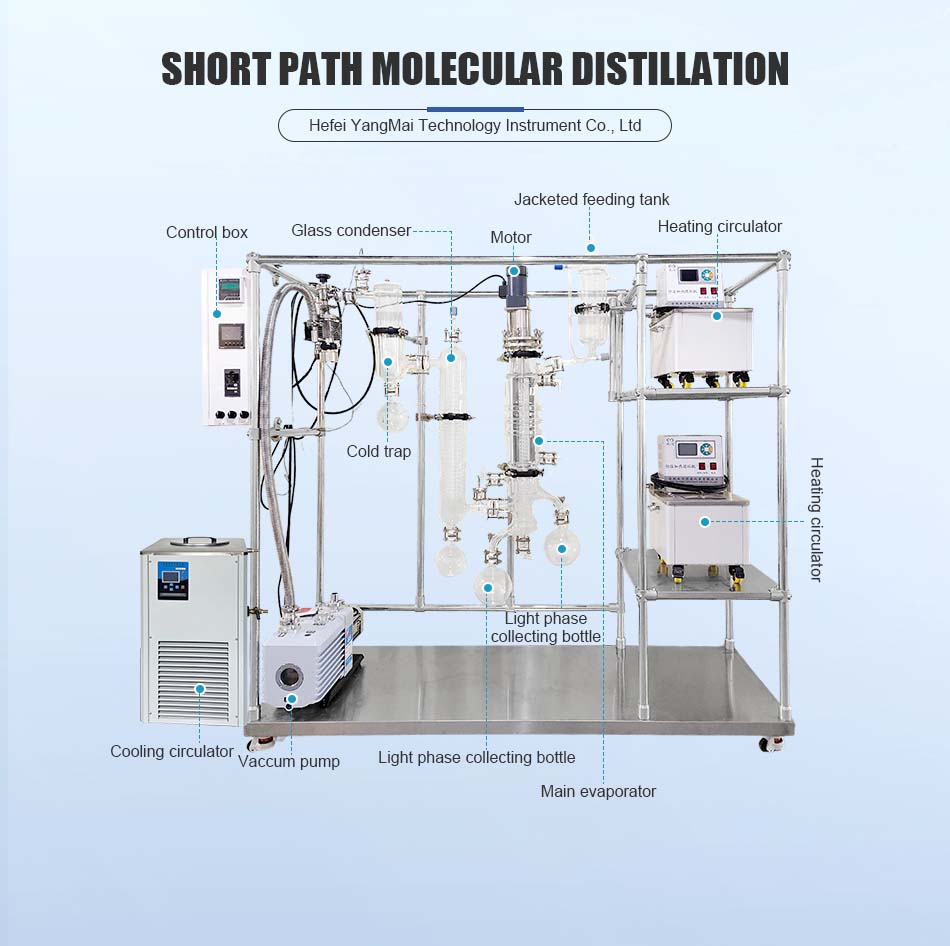

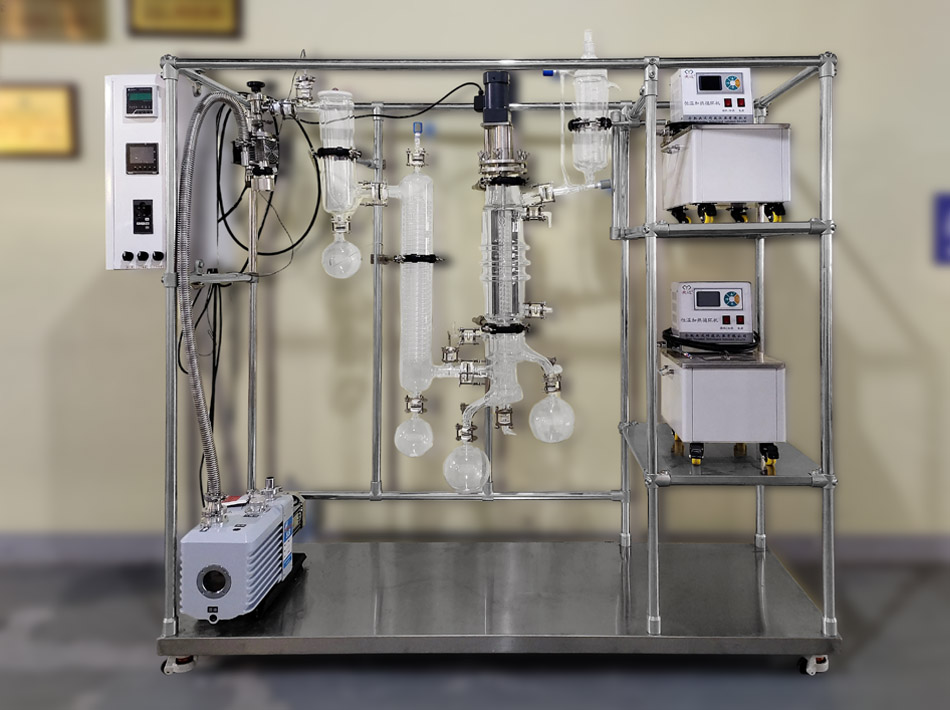

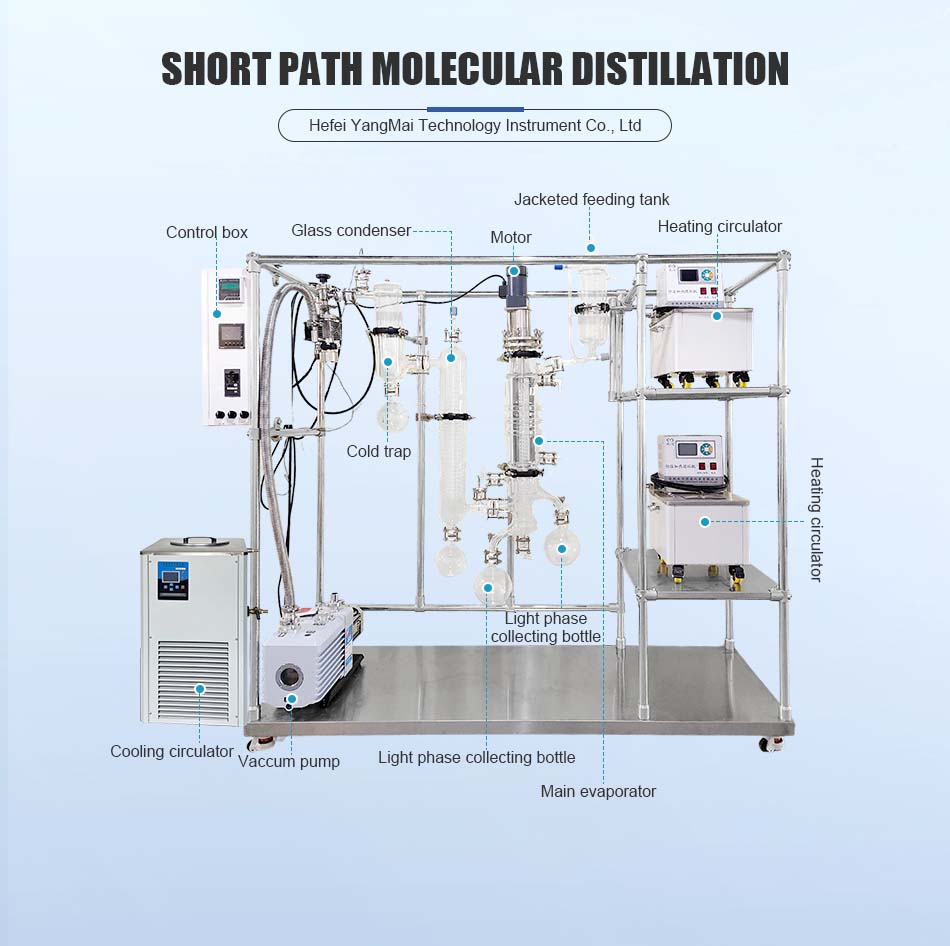

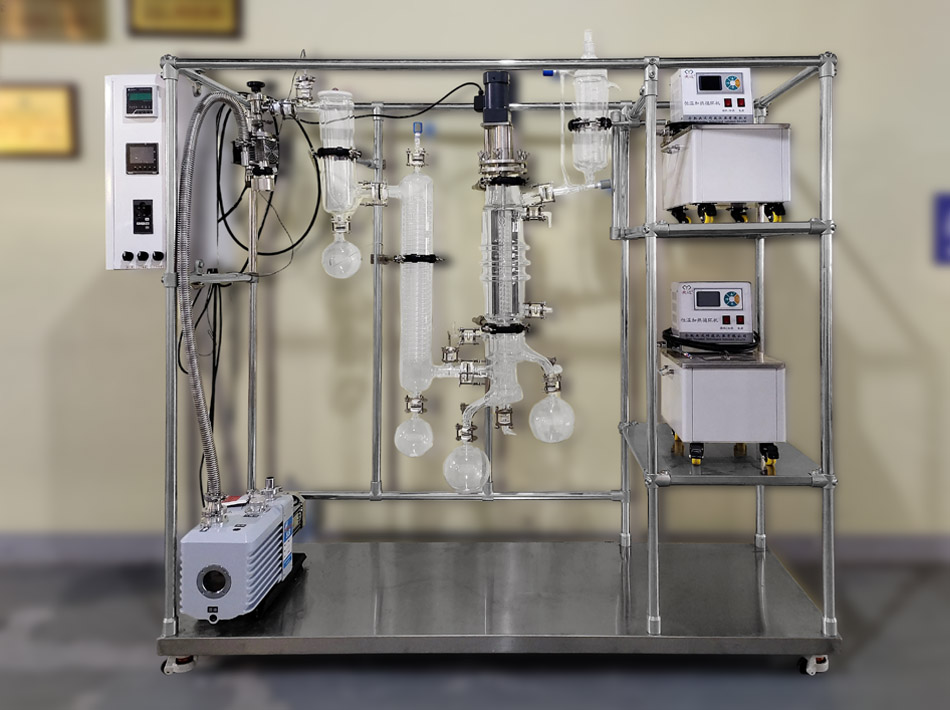

The Glass Molecular Distillation by Hefei Yangmai Technology Instrument Co., Ltd is engineered for precise separation of low-volatility or thermally unstable substances.It operates under deep vacuum conditions with minimal pressure drop, reducing residence time to seconds. Ideal for refining cannabinoids, terpenes, vitamins, and essential oils with high purity requirements.Its modular design allows quick integration into pilot-scale or industrial workflows. Constructed with corrosion-resistant stainless steel and borosilicate components for chemical durability. An intelligent control panel ensures stable thermal management and continuous feed operation.

| Model |

Evaporation area(m2)

|

Condensation area(m2) |

Main evaporator diameter(mm) |

Constantt Pressure feeding funel volume(L) |

Processing capacity(KG/h) |

Motor power |

Max Speed R/min |

| YMSPD-80 |

0.1 |

0.15 |

80 |

1 |

0.3~0.4 |

220V/140W |

600 |

| YMSPD-100 |

0.15 |

0.2 |

100 |

2 |

0.5~5 |

220V/250W |

600 |

| YMSPD-150 |

0.25 |

0.4 |

150 |

5 |

1.0~8.0 |

220V/250W |

600 |

| YMSPD-200 |

0.3 |

0.4 |

200 |

5 |

2.0~10.0 |

220V/250W |

600 |

1. Enables efficient heat transfer with shortened material dwell time, reducing thermal stress during separation.

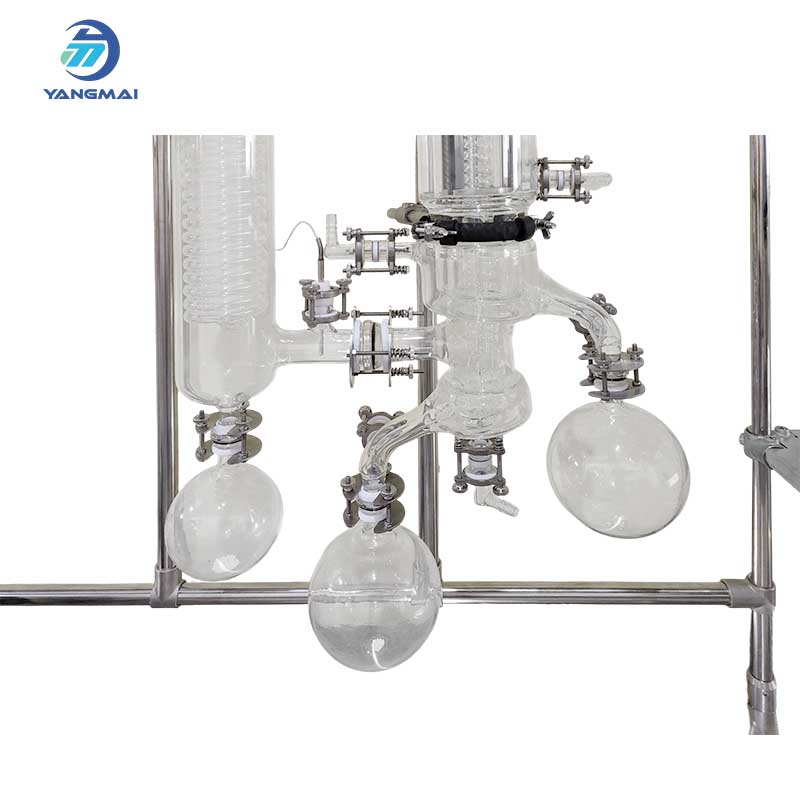

2. Built using chemically stable components—high-grade borosilicate glass, PTFE sealing parts, and stainless steel 316L framework.

3. The evaporator column provides full visual monitoring of the process and is available in either glass or stainless steel build.

4. Smooth inner heating surface ensures even liquid distribution with minimal fouling or material sticking.

5. Uses a variable-speed drive motor with integrated cooling fan to guarantee continuous and quiet performance.

6. Advanced magnetic coupling system isolates the motor shaft from the vacuum zone, improving vacuum tightness and system life.

7. Accurate temperature control is maintained even at extreme operating conditions between 200°C and 300°C.

8. Ultra-low operating pressure enables molecular separation under 0.1 Pa for highly volatile or thermally unstable substances.

9. Customizable wiping film or rotating roller options allow flexible processing of viscous or impurity-rich materials.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.