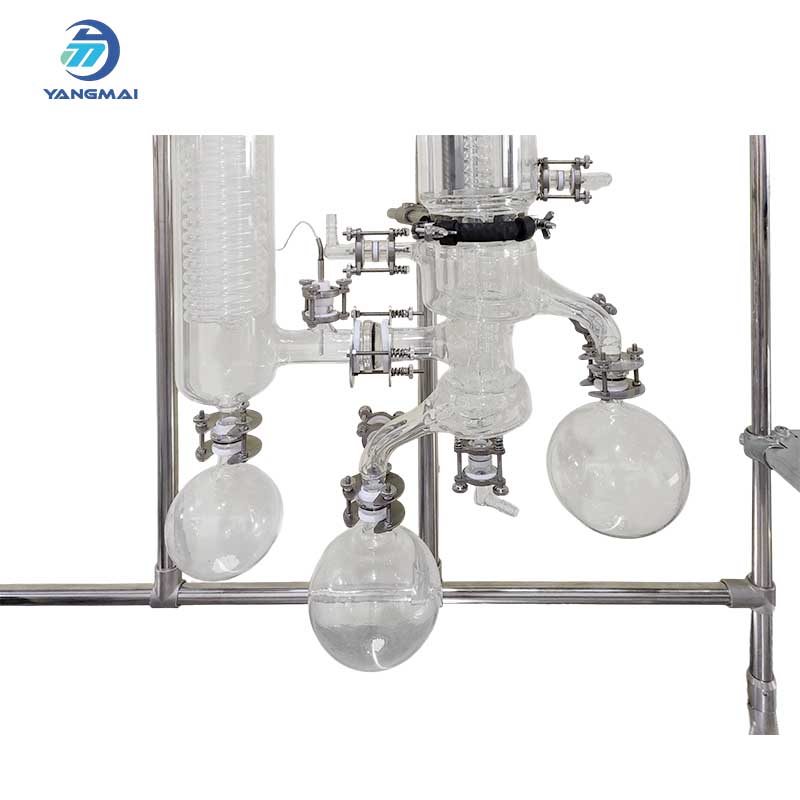

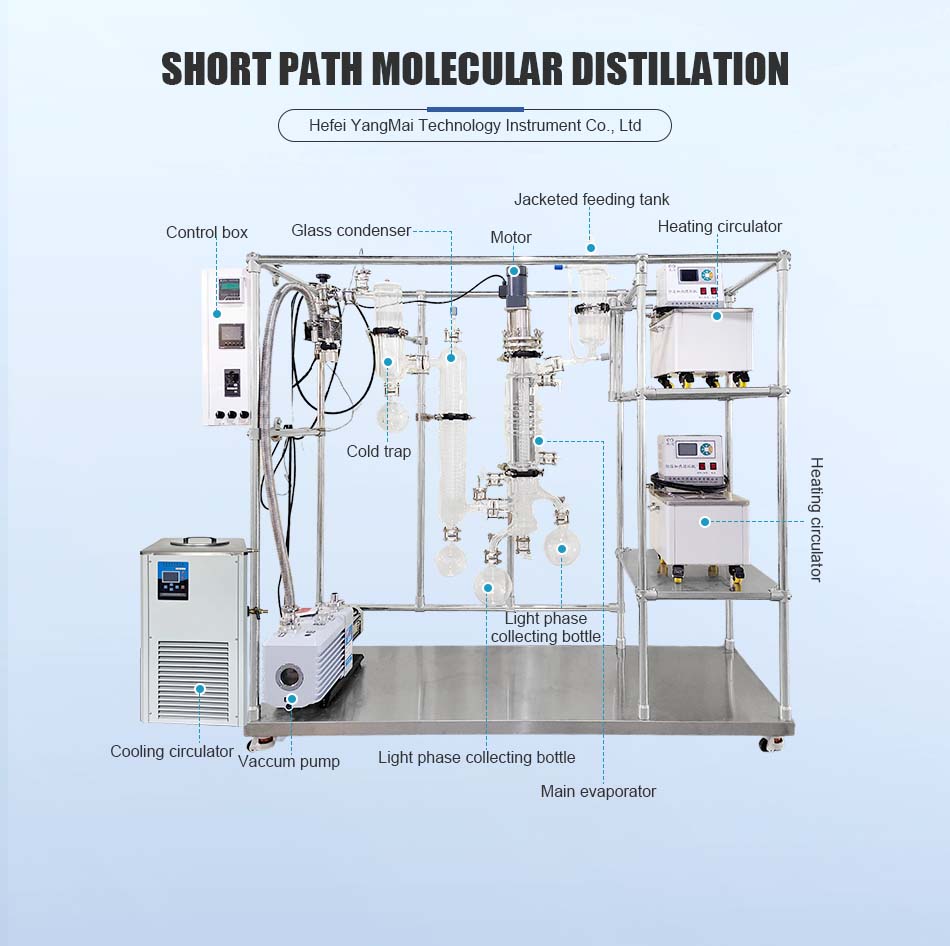

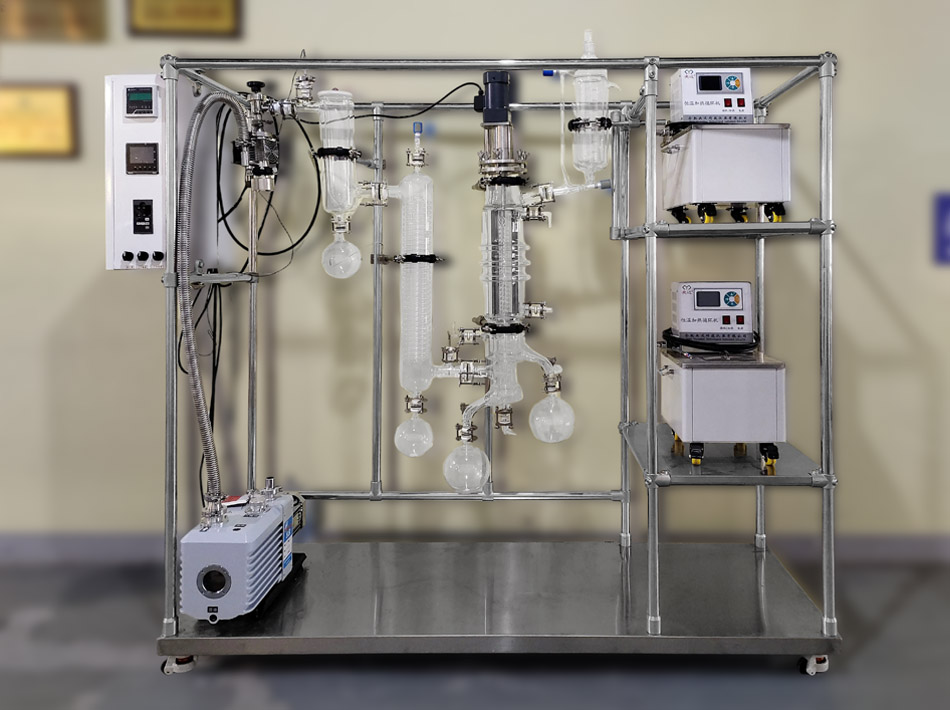

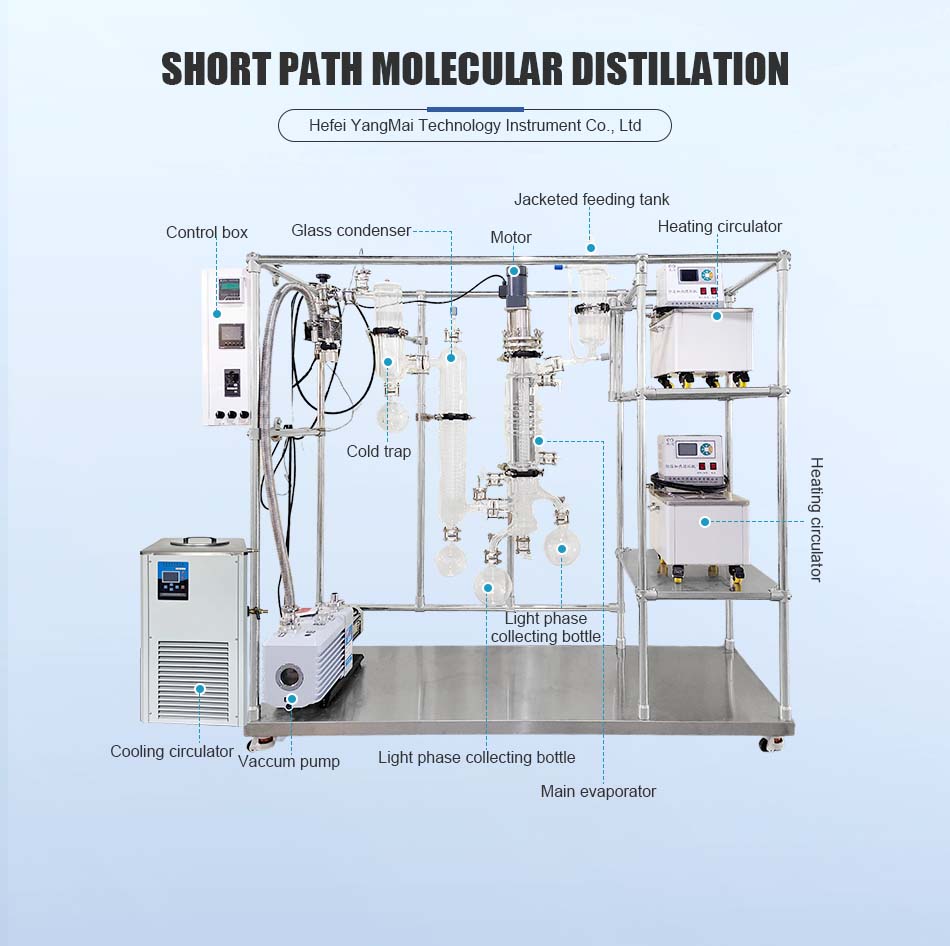

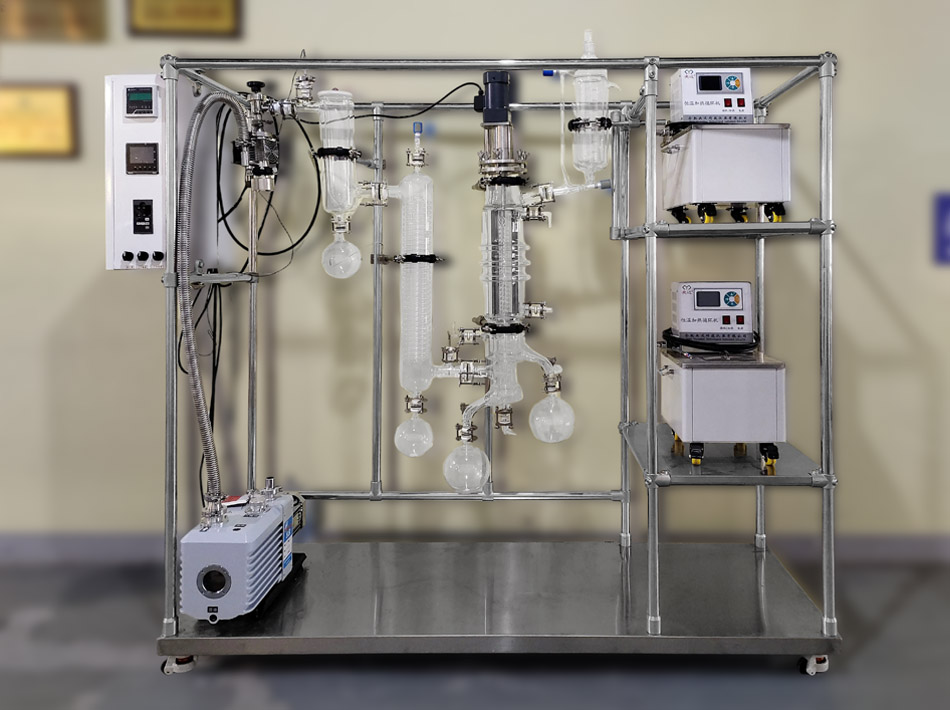

The Glass Molecular Distillation by Hefei Yangmai Technology Instrument Co., Ltd utilizes a rotating scraper system to spread materials into a uniform thin film along the heated surface, significantly enhancing heat transfer efficiency. Materials are introduced from the top and distributed radially onto the heating surface. As the scraper rotates, it pushes the film downward in a spiral motion, maintaining constant agitation and minimizing thermal degradation. This turbulence prevents fouling and scaling, making the system ideal for viscous and heat-sensitive substances. The light fractions are evaporated upward and collected via a vapor-liquid separator connected to a condenser, while heavier residues exit from the conical bottom. Commonly used in pharmaceuticals, essential oil processing, resins, food additives, and fine chemicals.

| Model |

Evaporation area(m2)

|

Condensation area(m2) |

Main evaporator diameter(mm) |

Constantt Pressure feeding funel volume(L) |

Capacity(KG/h) |

Motor power |

Max Speed R/min |

| YMSPD-80 |

0.15 |

0.2 |

80 |

1 |

0.3~0.4 |

220V/140W |

600 |

| YMSPD-100 |

0.25 |

0.4 |

100 |

2 |

0.5~5 |

220V/250W |

600 |

| YMSPD-150 |

0.3 |

0.4 |

150 |

5 |

1.0~8.0 |

220V/250W |

600 |

| YMSPD-200 |

0.35 |

0.5 |

200 |

5 |

2.0~10.0 |

220V/250W |

600 |

1. Offers rapid evaporation with minimal hold time, ensuring faster processing and low thermal degradation.

2. Constructed with corrosion-resistant materials like borosilicate glass 3.3, PTFE, and 316L stainless steel for chemical durability.

3.Transparent evaporation chamber made of borosilicate glass allows full visual control; stainless steel version optional for industrial customization.

4. Precision-engineered inner walls promote uniform liquid film formation and prevent residue buildup or scaling.

5. Equipped with a frequency-controlled motor and built-in cooling system for stable, long-duration operation.

6. Features magnetic drive technology for full sealing—no direct contact with vacuum chamber—maintaining system integrity at pressures as low as 0.1 Pa.

7. Supports high-temperature processing up to 300°C with fine thermal control for sensitive substances.

8. Capable of achieving ultra-deep vacuum levels down to 5 Pa or 0.1 Pa under ideal conditions.

9. Offers options of scraper-style or self-cleaning roller film systems to suit different feed materials.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.