The Borosilicate Glass Reducer from Hefei YangMai Technology Instrument Co., Ltd is an essential connector for laboratory and pilot-scale setups, allowing seamless adaptation between glassware of different diameters. Crafted from premium borosilicate 3.3 glass, it provides outstanding resistance to high temperatures, chemical corrosion, and mechanical stress. Its smooth inner wall minimizes turbulence, making it ideal for processes such as organic synthesis, fractional distillation, solvent recovery, acid-base reactions, and vacuum filtration. Suitable for research laboratories, pharmaceutical development, and chemical processing plants, this reducer ensures leak-free operation and long-term durability. Perfect for upgrading or customizing your glass reaction systems.

| Specification |

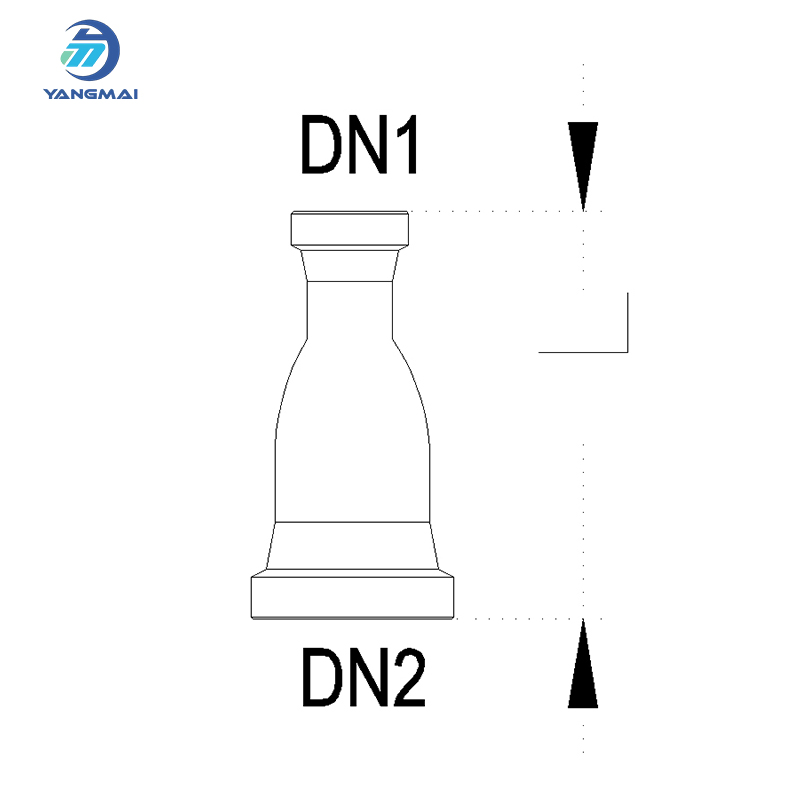

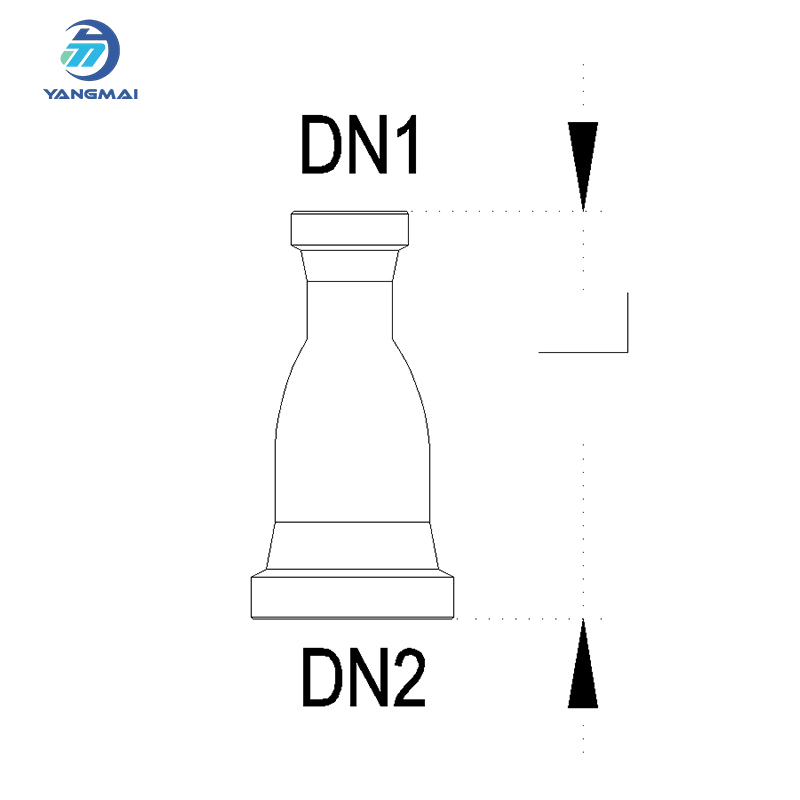

DN2

mm

|

DN1

mm

|

L

mm

|

| 1/2" |

25 |

15 |

100 |

| 1" |

40 |

15-25 |

100 |

| 2" |

50 |

15-40 |

120 |

| 3" |

80 |

15-50 |

150 |

| 4" |

100 |

15-80 |

200 |

-

Premium Borosilicate 3.3 Glass – Ensures excellent thermal and chemical resistance for demanding lab environments.

-

Smooth Inner Surface – Reduces flow resistance and prevents residue buildup during chemical transfer.

-

Universal Diameter Adaptation – Connects glassware of different joint sizes with secure sealing.

-

High Thermal Shock Resistance – Withstands rapid temperature changes without cracking.

-

Corrosion-Resistant Material – Ideal for handling acids, alkalis, and organic solvents.

-

Vacuum-Compatible Design – Supports leak-free operation under reduced pressure conditions.

-

Precision Ground Joints – Provides stable connections for reliable performance.

-

Clear Transparency – Allows easy monitoring of liquid flow and reaction progress.

-

Lightweight Yet Durable – Easy to handle without compromising structural strength.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.