The Glass High Groove Tank from Hefei YangMai Technology Instrument Co., Ltd is made from 3.3 borosilicate material, offering outstanding resistance to thermal shock, corrosion, and chemical attack. With a vertical, narrow design, it is optimized for efficient fluid handling and collection in pharmaceutical, chemical, and academic labs. Its transparency ensures precise observation during use.

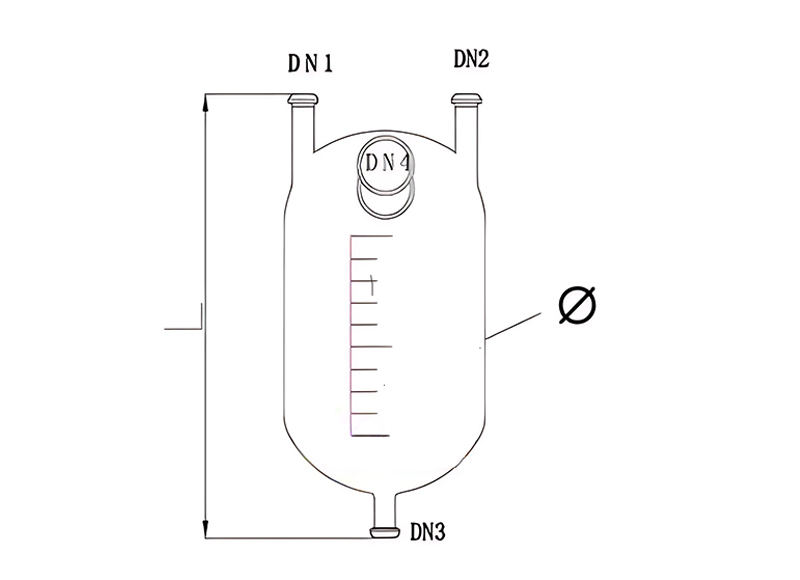

| Volumn |

∅ |

DN1 |

DN2 |

DN3 |

DN4 |

| 10 |

230 |

25-50 |

95# |

| 20 |

230 |

| 30 |

230-300 |

| 50 |

300-365 |

| 100 |

365-410 |

95-125# |

| 150 |

410-460 |

| 200 |

460 |

25-80 |

| 250 |

500 |

-

High Borosilicate Glass Construction

Manufactured from 3.3 borosilicate glass, offering excellent thermal and mechanical strength for demanding lab and industrial applications.

-

Superior Chemical Resistance

Inert to most acids, alkalis, and solvents, making it suitable for a wide range of chemical processing environments.

-

Precision Molded Groove Design

Features high-precision internal or external grooves that facilitate fluid distribution, separation, or guiding functions.

-

Thermal Shock Stability

Can withstand rapid temperature changes without cracking or deforming, ideal for heating/cooling cycles in research settings.

-

Ideal for Continuous Liquid Flow

Optimized structure supports steady liquid movement, drip control, or vacuum-assisted processes.

- Custom Size and Port Options Available

Multiple sizes, joint types, and connection ports can be customized to meet specific equipment or workflow requirements.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.