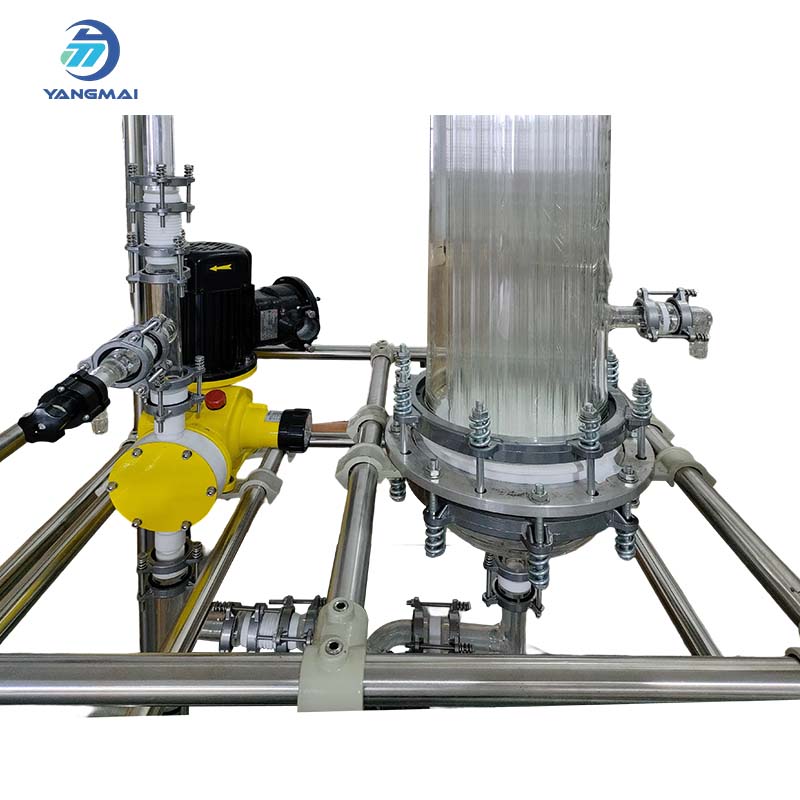

The 50 Square Meter Glass Falling Film Evaporator by Hefei Yangmai Technology Instrument Co., Ltd is a vertical-tube system used for concentrating liquid solutions efficiently. It features a glass tube heat exchanger, cyclone separator, coil condenser, and precision fittings, all made from durable high borosilicate glass. The system handles heat-sensitive substances like acids, alkalis, phosphoric acid, colloids, and plant extracts with ease. It is ideal for recovering chemicals from industrial wastewater, concentrating food products like juice and vitamins, and processing pharmaceuticals. This equipment also supports alcohol recovery and wastewater treatment in chemical manufacturing.

| Model |

YMFFE-01 |

YMFFE-5 |

YMFFE-10 |

YMFFE-20 |

YMFFE-30 |

YMFFE-50 |

| Evaporator volume |

10L/H |

20L/H |

30-50L/H |

80-120L/H |

120-200L/H |

200-300L/H |

| Evaporator area |

1m2 |

5m2 |

10m2 |

20m2 |

30m2 |

50m2 |

| Usage scenario |

Test |

Test |

Pilot scale |

Pilot scale |

Pilot scale |

Mass production |

1. Efficient Vertical Tube Design

Utilizes a gravity-driven, vertical falling film evaporation process that ensures rapid heat transfer and uniform liquid distribution for high evaporation efficiency.

2. High Borosilicate Glass Construction

All contact parts, including the heat exchanger, cyclone separator, and condenser, are made of 3.3-grade borosilicate glass, offering excellent transparency, thermal stability, and resistance to acids, alkalis, and corrosion.

3. Short Residence Time

Designed for thermally sensitive materials, the system enables quick evaporation with minimal thermal degradation, preserving active ingredients and volatile compounds.

4. Clear Visual Monitoring

The glass construction allows real-time observation of flow behavior, film formation, and vapor-liquid separation, ensuring greater control over process conditions.

5. Modular and Customizable System

The evaporator components are modular, making it easy to clean, assemble, upgrade, or connect with external chillers, vacuum pumps, or receivers based on application needs.

6. High Heat Transfer Efficiency

Maximizes energy efficiency through continuous thin-film formation on the inner tube walls, enhancing the surface area for heat exchange.

7. Safe for a Wide Range of Applications

Suitable for processing corrosive and amorphous solutions such as hot phosphoric acid, chromic acid, copper sulfate, and organic extracts, especially in cases where long-term heating is undesirable.

8.Multi-Industry Use

Commonly used in the pharmaceutical, chemical, food & beverage, and surface treatment industries for applications like solvent recovery, wastewater treatment, and liquid concentration.

RFQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.