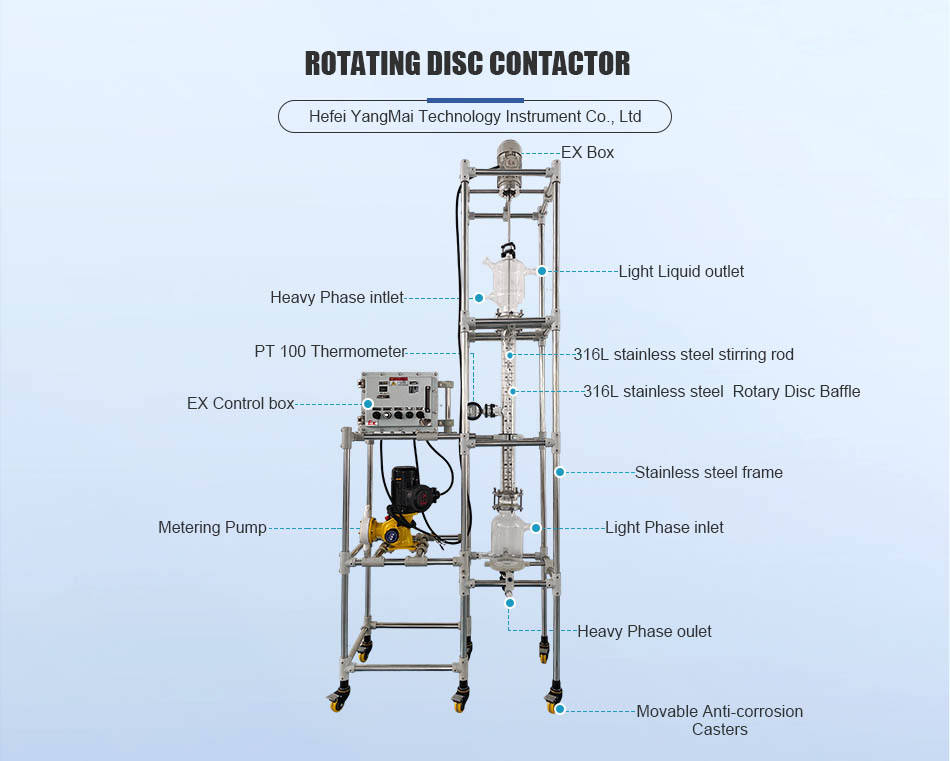

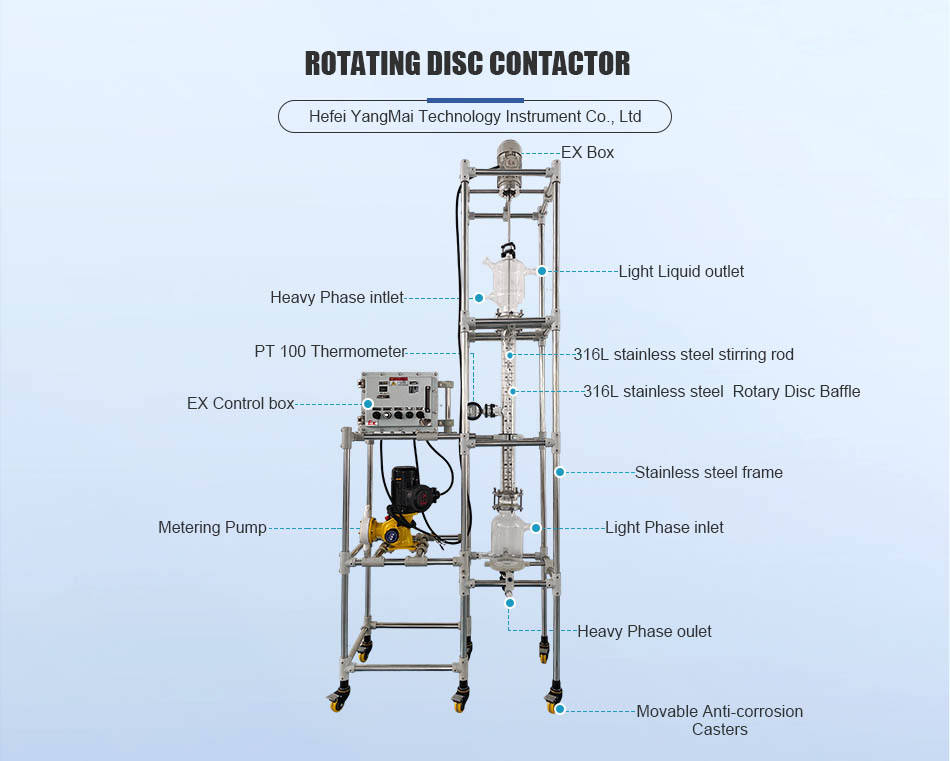

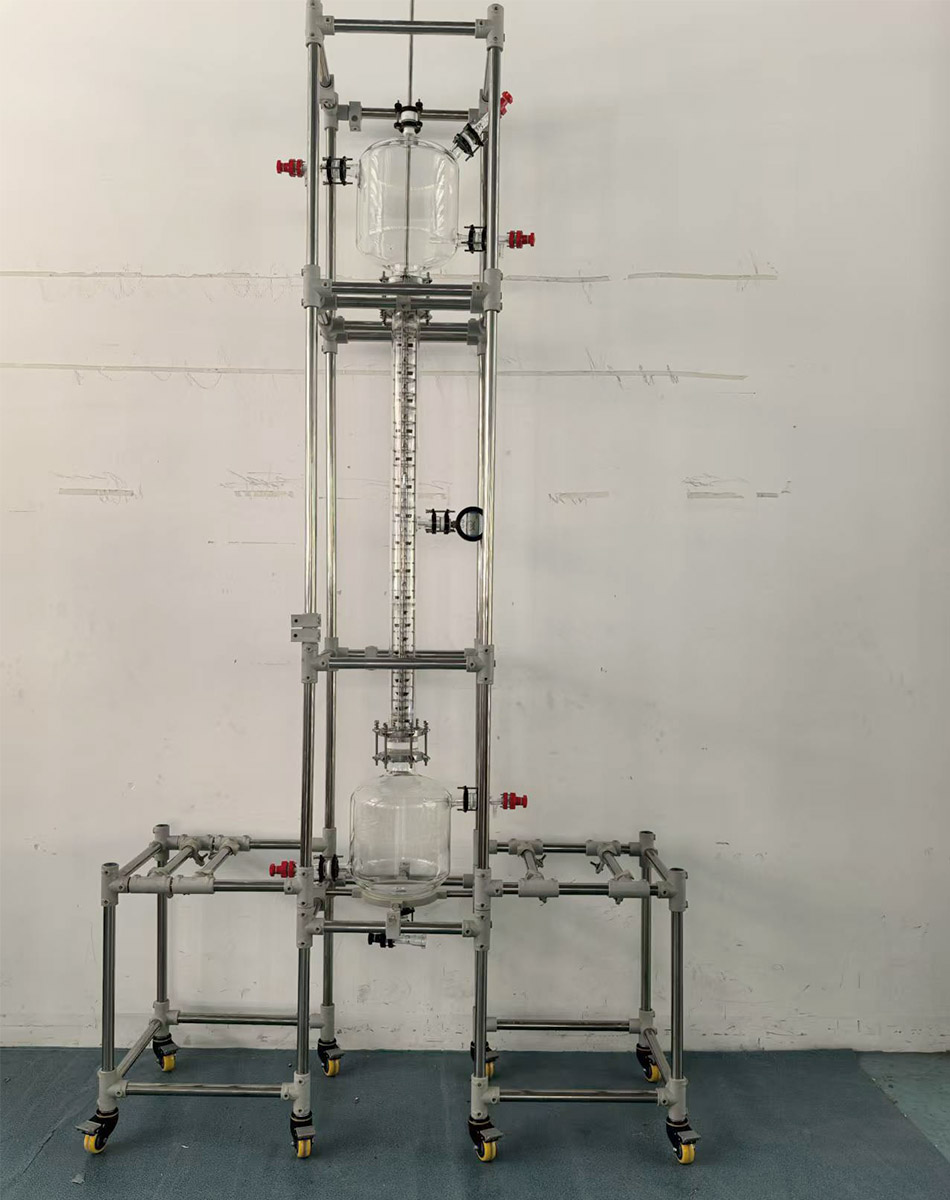

The Glass Rotating Disc Contactor by Hefei Yangmai Technology Instrument Co., Ltd. is a highly efficient liquid-liquid extraction tower engineered for advanced separation processes in industries such as chemical manufacturing, pharmaceuticals, petrochemicals, and environmental treatment. Featuring a vertical cylindrical body, it integrates motor-driven rotating discs and stationary rings to generate powerful shear forces, promoting intense mixing between two immiscible liquid phases.

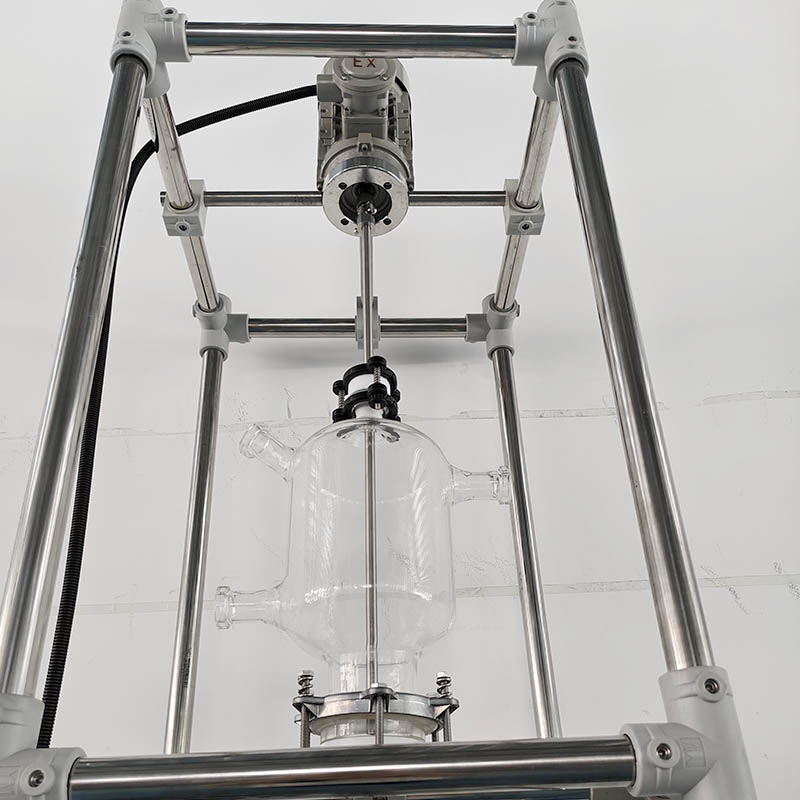

1. Precision Rotary Extraction Mechanism: The rotating internal plates ensure uniform contact between solvent and feed material, delivering highly efficient mass transfer for small-scale chemical and pharmaceutical extractions.

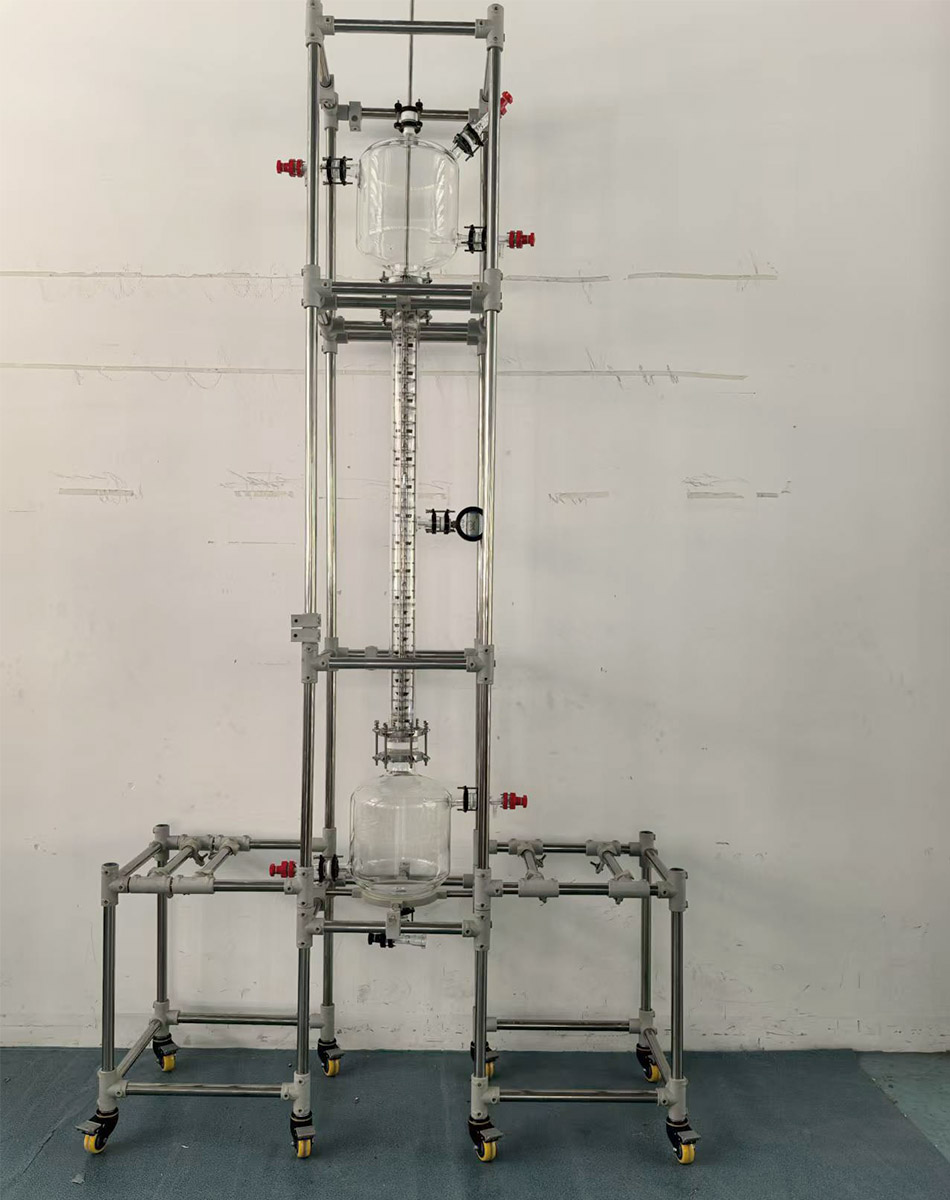

2. High-Clarity Borosilicate Glass Body: Constructed from 3.3 borosilicate glass with enhanced chemical resistance, allowing full visual monitoring of phase separation, liquid flow, and extraction stability.

3.10-Liter Laboratory-Scale Capacity: Ideal for research labs, pilot plants, and formulation development where controlled test batches and repeatable extraction results are required.

4.Compact Vertical Tower Design: Saves laboratory space while maintaining strong phase distribution efficiency, optimized for benchtop or fume hood installation.

5.Optimized for Two-Phase Liquid Separation: Engineered for solvent–solute extraction, aqueous organic separation, botanical extraction, and fine chemical purification.

FAQ

1. Are you manufacturer or trading company.

We are manufacturer.

2. Do you accept customized solution and OEM?

Yes, we provide fully customizable solutions to meet the specific needs of our customers. Whether you need modifications to an existing product or a completely new design, our R&D team works closely with you to deliver tailored solutions.Accept OEM too.

3. Do you provide after-sales service?

Yes, we offer comprehensive after-sales support, including:

Installation guidance.

Operational training.

Maintenance and troubleshooting.

Quick replacement for defective parts under warranty.

4. Can your products be shipped internationally?

Yes, we have experience exporting our products to customers worldwide. We work with reliable logistics partners to ensure safe and timely delivery to your location.

5. How can I place an order?

You can place an order by:

Contacting us directly: via email, phone, or our official website.

Requesting a quotation: Provide details about your requirements, and we will guide you through the order process.